The Severn Tunnel is a Victorian engineering marvel. And until the arrival of High Speed 1 in 2007, it was comfortably the longest main line railway tunnel in Britain.

At almost 4½ miles long, its 76 million brick-lined bore has kept out the waters of the mighty Severn estuary for 130 years, while providing a crucial subterranean link for the intensive passenger and freight flows between England and South Wales.

Equally well documented is the continuous battle against the water below, ever since the infamous freshwater source known as The Great Spring was unwittingly discovered by Navvies near the Welsh side in 1879.

Catastrophic flooding inundated the works, delaying completion until 1886 (14 years after the first spades had been put in the ground). A steam-powered pumping system and an elaborate maze of drains had to be put in place - at great time and expense - to hold the tidal water at bay.

Electric pumps were eventually installed in the 1960s, at Sudbrook on the Welsh side of the river. These continue to extract 10-20 million gallons of water daily to prevent flooding, while a continuous culvert runs between the tracks to collect groundwater and take it to the pumps.

Such damp conditions not only presented a major headache for the Great Western Railway’s engineers and principal contractor Thomas A. Walker during the tunnel’s construction, they have persisted into the 21st century, as Network Rail now prepares to electrify this section of the line as part of the ongoing Great Western Route Modernisation.

Although there is a great deal of clearance underground for overhead wires, new hybrid Intercity Express Programme (IEP) trains will instead be powered via a rigid overhead conductor system (ROCS), which is conditioned to fare far better in the tunnel’s corrosive environment and which requires less maintenance than conventional catenary in this confined space.

A six-week blockade was completed towards the end of October, to allow 250 NR contractors to install more than eight miles of ROCS (RAIL 809) prior to the route between Paddington and Cardiff being energised in 2019.

The damp atmosphere of the tunnel is equally unforgiving to steel rails - diesel fumes from passing trains combine with water to eat away at the track, necessitating its replacement every six years.

Electronic equipment does not fare much better - the moisture and humidity makes track circuits so prone to failure that in 1987 British Rail was forced to install axle counters instead, in order to mitigate increasingly frequent signalling failures and serious disruption to services.

It was this decision by BR that provided the backdrop to the events of December 7 1991, when a collision between two trains resulted in the most serious incident to ever occur within the tunnel, leaving 185 people injured.

Under normal circumstances, the tunnel was operated as one long signalling block, with the number of axles recorded as a train entered and then left the tunnel. ‘Line clear’ could only be indicated for another train to enter the tunnel if both counts were the same.

An equipment failure two days earlier meant that on December 7 trains were being worked through the tunnel under emergency procedures, using handsignalmen located at the signals at both portals to enable the trains to Pass the Signals at Danger, and to proceed at caution under the authority of the signalman located at Newport signal box on the Welsh side.

That morning, Driver David Robertson approached the signal guarding the east portal at danger and brought his train - the 0830 Paddington-Cardiff formed of an HST - to a stand. With no handsignalman present, he waited for about a minute before putting on his yellow vest and walking over to the signal in order to speak to the signalman.

The signalman told him there had been some technical problems, and instructed him to pass the signal at danger but obey all others. Robertson got back in his cab, gave a long blast of the horn, and entered the tunnel.

The time was approximately 1034 when, having descended the 1-in-100 gradient at a speed of 20mph from the English side for a distance of three miles, Robertson rounded the tunnel’s slight left-hand curve and prepared to apply power for the rising 1-in 90-gradient that made up the last mile to the west portal.

But before he could pull the power controller any further back he felt a sudden impact followed by an automatic application of the brakes, quickly bringing his train to a halt. Naturally his first thought was not that another train could be behind him in the same section, and given the ease with which he would have been able to see any obstruction that emerged in front of him while travelling at relatively slow speed, he suspected the HST had derailed.

Stepping down from the cab, his first action was to snap the breakable ‘tell-tale’ emergency wire that ran along the Down sidewall of the tunnel, triggering an audible and visual warning in Newport signal box.

One hundred yards in front of him was a telephone, enabling Robertson to report the impact to the signalman and to tell him that he was going back to inspect his train. Halfway down the length of the train he met the HST’s conductor, who told him that the rear power car was now standing 20 to 30 feet from the rest of the train, although neither it nor the train had derailed.

The conductor also told him that directly behind them and also on the Down line there was a two-car Class 155 Sprinter with a badly injured driver. At this point Robertson made a second phone call requesting emergency services, before returning to the HST to assess the condition of its 129 passengers and await further instruction.

The second train was the 0700 Regional Railways Portsmouth Harbour-Cardiff service that had followed the HST into the tunnel at approximately 1026. It had 168 passengers and two employees aboard, including conductor Brian Nicholl.

He told the subsequent accident inquiry that the train was running about 20 minutes late, and had not long since stopped at Patchway, when it slowed down to walking pace at the English end of the tunnel near Pilning. When the engines changed tone he concluded that the signal must have been red but had then turned to green, and the Class 155 started to pick up speed as it descended into the tunnel.

Continuing in his ticket inspection duties, Nicholl estimated that the Sprinter was travelling at 30mph when he was thrown in the air by a violent impact a few minutes later. Shaken but fortunately uninjured, he made his way to the cab to check on driver Stephen Carpenter, and on hearing a faint response sprang into action to protect his train.

Having placed track circuit-operating clips on the tracks in accordance with regulations (despite no track circuit operating in the tunnel), Nicholl found a telephone 200 yards away and told the signalman there had been a serious accident. He also gave the location tally number of the phone.

On re-entering the train, which had lost power and was illuminated by emergency lighting, he used the PA to call for medical assistance, and a doctor and several nurses came forward to treat the most badly injured. These included the driver, who was trapped behind a door jammed shut by the buckling of the cab floor. This was eventually forced open, and he was discovered to be badly bleeding from facial wounds and a fractured skull inflicted by a wall-mounted fire extinguisher that had been propelled from its fixings.

Among the passengers, one person was in a critical condition with a broken leg and suffering shock from blood loss, two or three had broken arms, four people had spinal injuries, and an estimated 75 had assorted facial injuries such as broken jaws and lacerations caused by falling luggage and being thrown out of their seats.

There were less serious injuries sustained

on the HST, but across both trains there were now at least 88 people who would go on to need hospital treatment, sat trembling in the cold and dark waiting for the emergency services to arrive.

British Rail had made some provision for emergency arrangements in the event of an incident occurring over 200 feet beneath the surface in the depths of Severn Tunnel.

An emergency train was stabled at Sudbrook Pumping Station, and on the English side agreements were in place to make a service diesel multiple unit (DMU) rapidly available for emergency use. A new dedicated command and control centre had recently been provided at Sudbrook for use by emergency services, while emergency drills had been practised in September 1990 with another due in February 1993.

On December 7 the ‘rescue’ DMU train arrived from the English side, travelling in the Down direction on the Up line, about two hours after the accident, with a team of paramedics and other equipment. The emergency train from Sudbrook arrived shortly afterwards, having inexplicably sat at the western portal for more than an hour before being authorised by signalmen to enter the tunnel at caution, also on the Up line.

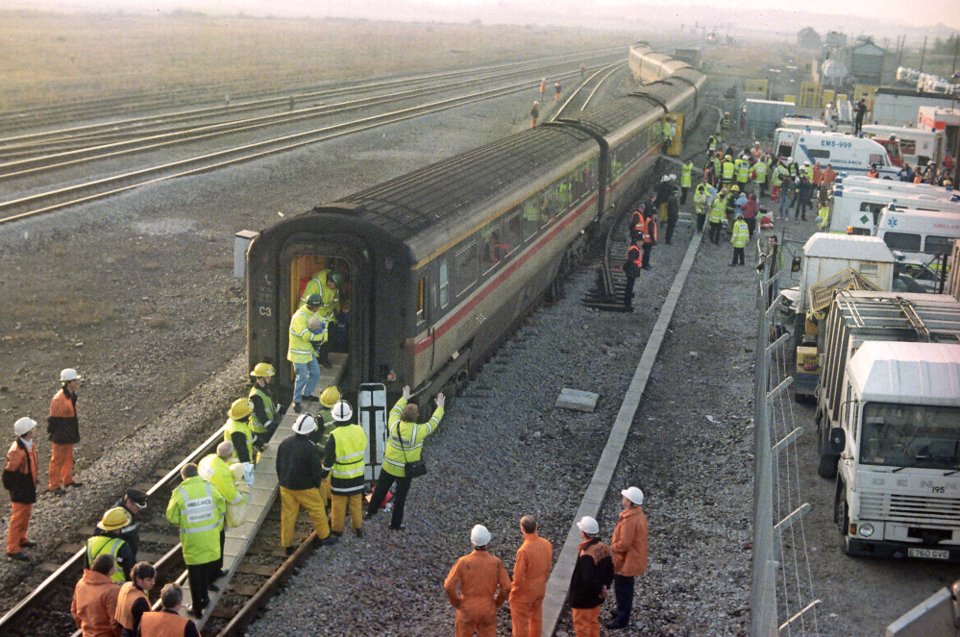

A controlled disembarkation of the Sprinter then took place, with those who could walk helped onto the HST and 17 stretcher cases also taken off. It would not be until almost four hours after the impact that driver Robertson was then finally instructed to drive his train forward and out of the tunnel at 5mph to Severn Tunnel Junction, where ambulances waited to transfer the injured onwards to hospitals throughout South Wales. The remaining passengers were taken to Caldicot Leisure Centre, and then by coach to Newport and Cardiff stations.

The damaged rolling stock was recovered from the tunnel that evening, and after inspections the following day established that no structural damage had been inflicted, the tunnel was reopened at 0530 on December 9.

The subsequent accident inquiry conducted by Her Majesty’s Railway Inspectorate focused on both the cause of the accident and why it took so long for emergency services to respond, leaving hundreds of terrified passengers trapped for a number of hours (with the risk of death had more life-threatening injuries been sustained).

The obvious question for HMRI was why the Sprinter had entered the tunnel when the HST ahead was still travelling through at caution, as it had been earlier instructed. The Sprinter driver Stephen Carpenter was advised against giving evidence by his lawyers, making it impossible for the inquiry to ascertain whether the signal changed from red to green as he approached it. Nobody else was in a position to testify, as the handsignalman had been withdrawn and the aspect was not visible to anyone else on the train.

Because the signal had not been changed by the signalman (and nor had he given authorisation for the Sprinter to pass the signal at danger), evidence was heard that a possibility existed (although highly unlikely) that the signal could have been cleared at the critical moment by technicians working in a relay room at Severn Trent Junction, resetting the axle counters that had suffered a malfunction two days earlier.

Signalling experts disagreed over whether this could have happened when the axle counter was disabled, and so the inquiry could not draw any firm conclusion. The only other reasonable explanation was an ‘unaccountable error’ on the part of Carpenter, who did not give evidence to either confirm or deny having passed the signal at danger without first seeking authorisation from the signalman.

The final accident report also heavily criticised the effectiveness of the emergency response, finding that although the emergency planning was perfectly adequate, its implementation was not.

A depressing catalogue of errors was exposed, starting with the breaking of the tell-tale wire being wrongly interpreted at Newport signal box as a technical failure rather than a genuine emergency, due to a history of false alarms. The precise location reported by the HST driver was then not properly communicated in the early stages, before most of the pagers issued to the BR rescue team based at Sudbrook failed due to lack of maintenance or not being switched on.

The delays in getting the Sudbrook train into the tunnel and then the HST out were caused by the need to obtain authority to pass a signal at danger under the tunnel’s emergency procedures, and the signalman having to liaise with emergency services occupying the tunnel in an area known for poor radio coverage.

The signalman’s decision to withdraw the handsignalmen before the collision was also dismissed as “improper”, although it was recognised that the use of a handsignalman is a convenience rather than a necessity, to enable a driver to be given authorisation to pass a signal at danger without having to leave the cab and phone the signalman themselves.

The accident report’s recommendations, therefore, were that wherever axle counters were used BR should make provision for resetting to be placed under the control of the signalman (rather than technicians), and that improved means should be provided for isolating them from the signalling system.

BR was also required to review the emergency procedures for the tunnel area, to ensure objectives are clearly established and state of preparedness regularly monitored.

No obvious contravention of any Health and Safety legislation was found, and the tunnel’s excellent safety record was commended - only two minor train accidents had been recorded in over a century of operation.

That impressive record has thankfully continued unblemished since the events of December 7 1991.

Login to comment

Comments

No comments have been made yet.