Cornwall’s clay traffic has changed in recent years. Traffic is supposedly in decline - the famous ‘Silver Bullet’ wagons no longer serve the area, and instead run through the Channel Tunnel, and continue to serve Irvine.

But there are still trains running in Cornwall. And DB Schenker will tell you that they are running in a more efficient way.

Rather than a few Type 3 locomotives running along branches with small trains of eight or nine wagons, today there is one Type 5 (Class 66) hauling 38 CDA wagons on trains. It may not be as interesting for the observer, but it is efficient and delivers what the customer (Imerys) wants.

The trains run to Fowey Docks, from where the material is exported. On Mondays, Wednesdays and Fridays the ‘66’ hauls the train from Goonbarrow, while on Tuesdays and Thursdays it runs from Parkandillack. There are also stores at Trevisco that the trains serve.

These are relatively short distances as the crow flies, but the trains predominantly run over branch lines, and so are slower.

Until 1988, the trains used the famous ‘clay hoods’ that were synonymous with the once-extensive clay train operations in the Royal Duchy. The vacuum-braked OOV wagons had been built in the late 1950s, but owed much of their origin to an earlier Great Western Railway design. They carried 13 tonnes.

The OOVs transported hundreds of thousands of tonnes of clay, with 40% of the Fowey shipment traffic received by rail - equating to more than 700,000 tonnes in the 12 months ending September 30 1987 (their last full year of operation).

The customer was English China Clay (ECC), which had no desire to operate its own fleet of wagons as the ‘clay hoods’ approached the end of their working life. And so British Rail ordered its own fleet of wagons, with Doncaster Works awarded the contract.

In total, 124 CDAs were built. They are air-braked, and have a payload of 32 tonnes. They were closely based on the successful HAA merry-go-round hoppers, but fitted with a hood so that the cargo could be kept dry in transit. There were initial problems with clay sticking to the internal wagon sides during discharge, but this was rectified by the application of a coat of anti-stick compound.

The first revenue-earning train of CDAs ran on January 26 1988, and by February 11 the changeover from the ‘clay hoods’ to the new wagons was complete. The very last ‘clay hood’ train was the 1528 Lostwithiel-Carne Point on February 10, hauled by 37672.

Today, two rakes of CDAs are in use, with three stored at St Blazey. They are reportedly due for scrapping, although there are other parts of the DB business interested in them.

DB Schenker Customer Services Supervisor Daryl Hutchinson is based at St Blazey, and his role is to resource the flows and make sure all is well with the customer. At the once intensively used depot, he explains to RAIL how things work now. Unusually there is a spare Class 66 at the depot, which these days is not usually the case.

“It’s amazing how long the trains can take,” he says. “Sometimes they can be running ‘round the corner’, but they take a while to shunt.”

He says there are nine drivers and four ground staff based at the depot, plus two more staff who cover any shortfall. The staff cover routes to Westbury and Southampton, and Hutchinson explains: “They will also take the Cliffe Vale train to Exeter. Occasionally there is ballast work, but there is not much scope for much more.”

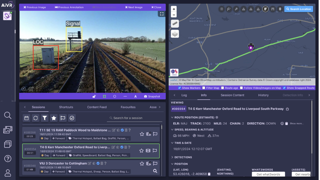

RAIL is here to see 66176 in action. This is the first DB Schenker locomotive to be successfully fitted with stop-start technology (RAIL 758).

The Auto Engine Stop Start (AESS) technology, manufactured by ZTR, will be fitted to 30 locomotives by the end of this year, and a further 60 in 2015. By the end of 2016, all 174 DB Class 66s based in the UK will be fitted with the technology.

DB Head of Maintenance and Infrastructure Andy Byrne says the move will save 4,500 tonnes of carbon emissions per year across the first 90 Class 66s. Tests on 66176 showed that the amount of time the engine was running was reduced by about one-third, cutting CO2 emissions by more than 50 tonnes (thus equating to the 4,500t for the 90 locomotives, a 10% reduction in emissions).

DB fitted the equipment to 66176 in February, and it has remained in Cornwall ever since, with the exception of when it has left for maintenance.

Byrne says AESS works like a modern car. A box (250mm long, 200mm high and 80mm deep, mounted in a small pre-existing and unused cabinet located in the vestibule behind No. 1 cab of the locomotive) is fitted to the ‘66’ with specific parameters set, regarding performance.

When the ‘66’ comes to a stand and begins to idle, the box will measure battery voltage, engine temperature and oil temperature. If these measurements meet the parameters, then the ‘66’ shuts down.

When power is applied, the ‘66’ will then take 10-20 seconds to ‘fire up’ and start moving. Byrne says this will not add time to journeys, because it is not a complete engine shutdown - some systems will still be operating.

Since receiving AESS, the ‘66’ has used 20,000 litres per year less than usual. Over the entire fleet of 174 locomotives, that represents a saving of almost 3.5 million litres.

Byrne says it has been deployed to Cornwall because the flows there use one depot (St Blazey), and there is a small team of drivers who are thus able to offer detailed feedback.

On the day of RAIL’s visit (October 15), it is working from Goonbarrow to Fowey Docks. In terms of distance this is a short journey, but it will take longer because the ‘66’ must run to Lostwithiel and then run round before heading down the Fowey branch. The latter is short (only four miles), and described by Hutchinson as a “gentle trundle”.

He notes that there have been a couple of issues with the technology on the ‘66’, but nothing major, merely what he calls “usual electrical equipment” faults. There were also a couple of problems with it firing up (but again nothing major), while the project leader has also been to Cornwall to reprogramme the ‘66’, following driver feedback.

While at St Blazey, Hutchinson tells RAIL: “It will shut down at Fowey and it may also do so at Lostwithiel.” He says the restart is “almost instant”.

In terms of training the drivers, Hutchinson says: “There was a briefing pack, but that was relatively short. There is not a lot to it.”

He says the system can be over-ridden, allowing the driver to dictate its use. This is useful in winter, because if the locomotive is employed on a possession then a driver does not want to be sat in a cold cab, so he can ensure that the engine is still running.

Today the ‘66’ is hauling 38 CDA wagons. DB has 82 in use - these run as two rakes of 38 with four spares, with two more always left at the unloading point at St Blazey. There are always two over the pit, and Hutchinson says that the system works “as there is always one over the system”.

The operations work from Parkandillack with a loaded set that runs to Fowey (the clay is exported from Fowey). This then returns to Goonbarrow. The other set is taken from Goonbarrow and returns to Fowey. The Class 66s are fuelled once a week, and this is done on a Saturday morning at St Blazey.

There is a second Class 66 in the region, which runs to Exeter hauling wagons from Par Docks. Hutchinson explains that this engine will load over two days and also go to Treviscoe. The trains from Par Harbour run to Exeter, but in two loads because of their weight.

The limit for a Class 66 to haul over the infamous Devon banks between Plymouth and Totnes is 1,000 tonnes, so it hauls the first rake to Exeter and then returns for the second load before continuing to Newport. It is later taken to Bescot.

On the morning of RAIL’s visit, 66176 had left Fowey Docks at 0522 with its rake of wagons. It ran to Goonbarrow, which took an hour.

The plan is that it will arrive at Fowey at about 0900. It will then begin unloading at around 1000, once a complicated shunt has been completed. Unloading the 38 wagons takes three hours, and the train departs (empty) at 1350. It then runs to Goonbarrow again, is loaded, and returns at 1630.

Says Hutchinson: “There is not much waiting around. We do have some leeway for delays if they are slight. Sometimes you can run round faster in Lostwithiel loop and get out in front of a passenger train. Other times you have to wait your turn.”

At St Blazey station, which closed to passenger services in 1925, RAIL waits for 66176. The station has two platforms, while the signal box still controls the junction to the depot. In pouring rain, the ‘66’ arrives at around 0730, driven by Jeff Hancock.

At Par the train is held in a loop while a First Great Western High Speed Train arrives and collects passengers bound for London. At the other platform 66065 is shunting a rake of wagons bound for Par Harbour.

Hancock says of the AESS system: “I would not be without it. I think it is helping the noise especially if you are there for a while. It will shut down after ten minutes and it is no effort to restart it.”

He’s also happy with how quickly it can start on a cold morning.

“If you asked for anything to improve now, it is for the AESS to talk to the EM2000 , which is the brains. If something occurs to prevent the ‘66’ starting, then the AESS will keep trying and that will spin the starting motor which eventually will burn out. That flattens the battery.” Hancock speaks of the field generator circuit breakers tripping, and the computer didn’t know how many times the locomotive had attempted to start.

“I think the majority of drivers’ concern is that the only thing that will not make it start is low batteries. It will start itself again. I could drop all the air, but the batteries could be good and it could run away. But, as drivers, we should scotch the locomotive anyway. So that should not be an issue.”

Today’s load is 1,835 tonnes (including 66176), so the train is 1,708t for a payload. The conditions are wet, and slippery uphill. Hancock started work this morning at 0430 at Fowey, and will finish at 1530. He has taken 66176 to Goonbarrow, Fowey, and will return it to St Blazey.

He has seen it all in Cornwall, and remembers the ‘Clay Hoods’. Recalling the introduction of the CDAs, and their subsequent use, he says: “When we started with ‘66s’ we had 24 on a train in a set, then it was 30, and now it is 38.”

As our train pounds along the Cornish Main Line, it noticeably slows. The cab environment is loud as the engine roars behind us, and yet the speedometer is dropping… 21mph… 17mph.

This is because the ‘66’ is climbing towards Trevarrin Tunnel, up a hill that twists and turns. It enters the tunnel at 12mph. XXx says it was a good climb, and that he has ground to a halt on the line several times. From the tunnel, it is downhill to Lostwithiel.

“I get half an hour to run round at Lostwithiel. It will shut down. We complained because it used to shut down after five minutes, but it is ten now.” He praises DB for listening to its drivers’ concerns.

Hutchinson chips in: “We leave it on at weekends. That uses fuel. We may ask what the point is, but it is looking at the system and will help with fuel and batteries.”

At Lostwithiel, the loop is the final part of an extensive railway system that is still used. It is adjacent to the Up line beyond the station, and next to former milk sidings that still have rails in them, although they are not connected to the main line.

Once the ‘66’ runs round its train, it couples on, and after an air-brake test we wait. An FGW Class 153 bound for Newquay passes, and then the ‘66’ shuts itself off.

There is an alarm to warn that this will happen, and a small light flashes in the cab. Hancock restarts it when needed, and 66176 fires up first time. “It probably has a better charge now than earlier,” he notes.

As we set off, he exchanges tokens with the signaller at Lostwithiel and descends onto the Fowey branch. This single-track line hugs the River Fowey all the way, and is stunning. The valley opens up in front of the train as it passes tree-lined river banks. The maximum speed is 30mph.

“I think at times people would pay for this view. It is such a pretty branch, and to think I am getting paid to see this,” he says.

The clay being transported today is largely bound for the Mediterranean and Egypt, for use in ceramics.

As the train approaches Fowey there is a pink building hidden away on the right. This is Sawmills Studio, where big-name musicians stash themselves away to record music. Hutchinson recalls the Gallagher brothers (from Oasis) being here.

Just beyond that is the entrance to Fowey Docks, and a weighbridge that the train passes over at between 0mph and 5mph. The wagons are unlocked as they pass over the weighbridge. This is air-operated. The arm comes out and unlocks the wagon by moving a catch. All 38 wagons are weighed in.

Once that is complete, the rake is split into two sets of 19. The first 19 are shunted into the unloading area, while the ‘66’ moves off to collect the second half, which it then backs onto the first half, so that all 38 pass through the unloading bay. One wagon will be left ready for the next train. There is already a wagon here from the last train.

There are two barrier wagons here. These are withdrawn CDAs, and have no brakes. When the ‘66’ pushes the wagons into the unloading facility, it uses the barrier to do so.

The wagons are then collected by the automatic loading facility (the Beetle), which moves them along like a conveyor belt. When a wagon is unloaded it is moved by gravity to the end of the siding, where it lands on a traverser. This then moves it across to the next siding, where the Beetle then moves it back into a siding.

A DB shunter then couples the wagons, and the ‘66’ can take them to their next destination. The rear wagon of today’s train will be left to become the front wagon of tomorrow’s train.

RAIL leaves the trains here and returns to Par, using the former Great Western branch that closed in 1968 and which is now a private road for Imerys. It passes the disused but intact railway station in the town. The road enters Par at the harbour, and soon RAIL is back at St Blazey.

With the Railhead Treatment Train at the depot, this means there are three locomotives on site. It’s almost like the old days.

Those days may never return, but the level of interest is still there. Cornwall remains a fascinating place for freight and innovation.

- This feature was published in RAIL 761 on 12 November 2014

Login to comment

Comments

No comments have been made yet.