The decline of coal is presenting a host of interesting dilemmas for the energy industry, as it seeks new ways to fuel its power stations.

Key to this will be biomass. But innovative ways will need to be found to enable rail to move the product across what will be (one day) the area covered by the ‘Northern Powerhouse’.

GB Railfreight started moving biomass in 2010, transporting the product from various east coast ports to feed power stations along the eastern side of the UK. (RAIL travelled with one such train from Port of Tyne last year, RAIL 751). And there has been significant investment by many companies, as rail and the energy sector look to develop this method of fuel.

Biomass looks like chicken pellets. It is shipped from the Americas (usually North America), and arrives in ports that are large enough to accommodate deep-sea vessels.

However, considering the UK is an island, there are not as many of these as you might think. Much like on the railway, capacity is also an issue at ports. Biomass is just one more product in a long list of imported goods vying for space not only on the railway, but also at ports.

GBRf ran its first train for Drax Power from the North West on October 26 (RAIL 787). The freight company has been operating in the region for many years, and this new train adds to the company’s portfolio. It runs from Port of Liverpool to Drax Power station (near Selby, in North Yorkshire), and carries 1,600 tonnes of biomass.

The freight company explained in a statement: “The Port of Liverpool is a loading location included on GBRf’s contract for hook and haul services with Drax Power. GBRf currently runs two sets of Drax wagons.”

59003 Yeoman Highlander, with 66706 Nene Valley on the rear, hauled the first train - it was formed of 25 of Drax Power’s biomass wagons, and left the Port at 1725 on October 26. The ‘59’ took the train up the steep bank to Tuebrook sidings (near Edge Hill), from where the ‘66’ continued the working. The train arrived at Drax Power Station at 0159 the following morning.

This is just the first part (Phase 1) of a grand five-year plan. The next phase will be completed next year - GBRf says the objective is to stimulate greater throughput at the new terminal, increasing trains from this location and ultimately using four sets of wagons to move up to three million tonnes of biomass per annum from Liverpool (Peel Ports) to Drax Power Station. The power station produced 12% of all of the UK’s renewable electricity in 2014.

GBRf Managing Director John Smith tells RAIL that the plan is for three sets to be used, working out at one and a half trips every 24 hours. “On a scale it is big, but not our biggest,” he says of the contract.

Smith explains that the Class 59/0 is being used for its haulage capabilities. It was not bought specifically for that reason, but since there is a lot of volume per train and a steep climb from Port of Liverpool, it makes sense to use the locomotive for the time being.

This new contract will also provide a massive boost for the region. The Liverpool Echo reported that 300 jobs would be created in the supply chain as a result. Meanwhile, related work at the Merseyside port, which is owned by Peel Ports, includes construction of a rail loading facility and a 100,000-tonne storage capacity.

The actual terminal is owned and operated by Ligna Biomass, which itself is owned by the shareholders of Peel Ports. It does not become fully operational until next July (Phase 2), at which point up to ten trains per day can run to north Yorkshire.

Work is still needed at the Port, however. “The railway runs parallel along the docks,” explains Smith. “The access is via a single 90° steel climb. I’m not sure what it is, maybe 1-in-100. So you start at 0mph on a curve, and the train is longer than others we run to Ironbridge. We are lobbying for this to be improved. There is a level crossing, and we want double track from that.”

Smith says funding for this would come from the Strategic Freight Network, which is designed to support such projects.

A major challenge has been to establish the paths for this new flow. A Rail Freight Group (RFG) report reveals that 58% of respondents to a recent survey believed that lack of suitable paths was a barrier to the growth of rail freight.

And the operation of these new trains certainly shows the length the industry needs to go to in order to operate freight. In recent years, the majority of freight crossing the Pennines has been residual traffic - the remnants of flows that had been running for years. There has not been a dedicated freight route since Woodhead closed in 1981 (passenger trains ended on that line in 1970).

Freight has had to battle for paths on the various lines that criss-cross the region, linking some of the UK’s busiest and most populated cities - Leeds, Sheffield and Manchester, as well as (further afield) Liverpool, Hull, Bradford, York and Newcastle.

It was two years ago that Drax began working with Network Rail and GBRf, identifying paths that were viable and which could support a train plan to and from the Port of Liverpool. Since then, GBRf has been working on making that a reality.

At the launch of the train, Smith said: “The running of the first biomass train for Drax Power from the Port of Liverpool is an important moment for GB Railfreight. Over the last two years, we have been working with Drax and the infrastructure operator to secure viable paths across the trans-Pennine rail network, and answer the demands of one of our longest and most loyal customers.

“Today is recognition of these efforts and the innovative approach we take to customer solutions. We’re looking forward to building on this relationship with Drax as we move into Phase 2 of the Liverpool project.”

Drax Head of Supply Chain & Logistics Graham Backhouse said: “This first delivery of sustainable biomass from the Port of Liverpool is further evidence of Drax powering the Northern Powerhouse.

“Using cutting-edge biomass technology we are transforming the UK’s largest power station into one of Europe’s largest generators of renewable electricity. Receiving biomass from Liverpool is another example of how we provide the UK with sustainable, reliable and affordable energy.”

At Drax there are six generators - three are biomass-powered and the rest are coal-powered. Drax Power aims to convert a fourth to be powered by biomass. This could result in even more traffic.

The route the trains take is certainly a circuitous one. Once the trains have climbed from the Port, they use Tuebrook sidings, which have been upgraded with staff facilities built there.

Smith explains: “Tuebrook is odd. The sidings have been used for tamper maintenance. They are on the right near Edge Hill. There used to be a tunnel that went to the Docks, and the locomotive runs into that a short distance. It runs round the train there. There are three sidings, and these were last used for electrification.”

He says the train arrives hauled by the ‘59’, which is unhooked and runs into the tunnel before a ‘66’ then takes the train to Drax. The ‘59’ is then attached to the next train to the Port, and the process begins again.

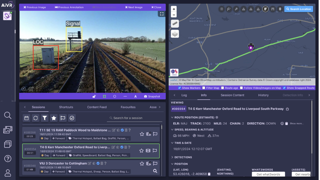

The biomass trains run from Liverpool to Warrington, then across to Northwich, Altrincham, Stockport and Rochdale. From there they head across the Calder Valley and then on to Wakefield, Knottingley and Drax. It is a 99-mile journey.

GBRf says that initially 13 trains per week will run, rising to 23 from mid-2016. The wagons are owned by Drax and have a capacity for 116 tonnes of product - 30% more than other UK wagons. The payload is 72t with a gross laden weight of 102 tonnes. Maximum speed is 75mph.

The train plan for the new biomass flow required detailed prepatory work, with particular attention paid to the sectional running times and close investigation of headways along the route from Tuebrook Sidings to Drax.

“Capacity is really constrained.,” reveals Smith. “Todmorden is the main route, and then it is across the top of Miles Platting Bank. That is a consideration we have to look at - do we need banking? I think the area has been rationalised, too, which means we have to wind our way through Manchester. It is not easy.”

Electrification is also an issue. Surely if the wires are put up, then the better acceleration of the electric multiple units will help improve access for freight?

“They’ll try and run more EMUs and they will go faster. We are better with the slower services,” replies Smith. On bidding for access, he says it is a case of freight versus passenger trains: “It is about pinch points, like around Stockport.”

However, Smith says that people are listening. He talks of devolution: “There are some consultations with Rail North. The difficulty is that you talk with people and they are interested, but the problem with most rail freight is that it crosses geographic boundaries.

“People need to understand the industries and the infrastructure it serves. I think they get it. The key is our right of access to the network. Capacity must be found for that. What comes next is to lobby for investment in infrastructure.”

He says the ports are driving this need for investment, as highlighted by this new deal. “The main ports are Liverpool, Tyne, Tees, Immingham and Hull, and it is about the connections into these. These ports are hugely important.

“Liverpool was coal and is now biomass. Ports need good access. Liverpool needs it.”

The trains form part of a much larger supply chain that serves the power station. Much of the biomass imported into the UK arrives at east coast ports such as Port of Tyne, Immingham and Hull, but using Liverpool gives the energy supplier dual-sourcing in the event of any interruption of supplies to the east coast ports or to their railway infrastructure and access.

In its application to the Office of Rail and Road, GBRf highlighted the issue of access following the derailment of a coal train at Brocklesby, and how that seriously disrupted traffic to and from Immingham for more than a week.

The application stated: “This is one of the UK’s largest and busiest ports, and resulted in a serious reduction in the tonnage of coal, biomass and other goods handled here, with a switch in ports being necessary. As a result of this, GB Railfreight lost almost 50% of its services and the first four to five days saw no trains out of the port at all.”

Drax’s need for biomass is huge. The energy supplier requires millions of tonnes per year, and there has to be as much certainty as possible on delivery - particularly on the rail side - to ensure that the company can meet the UK’s power requirements.

In its application, GBRf explains the difference between coal and biomass as: “Unlike dealing with coal for generation, the transportation of biomass is far more a ‘just-in-time’ operation, with the product needing to be kept under cover and, at worst, only being stored for a limited time before it is burned. Therefore, there needs to be tightly defined paths to give the ability for GBRf to deliver the required tonnage, seven days a week, and maintain a robust fuel supply into Drax Power Station.”

Smith explains: “Drax needs to know where the product is stored. Liverpool is also better protected. The economics help, too.”

He says that all three ports that Drax uses (Tyne, Immingham and Liverpool) will be running at around 70% capacity. This means that in the event of a problem whereby trains and ships need to serve a different port, there will be sufficient space to accommodate them. Thus the need for access and different routes was paramount.

Drax also saves time by using Liverpool, rather than the east coast ports. Docking ships from North America on Merseyside, rather than (say) the North East, saves about two days. This, combined with competitive port rates, drives commercial decisions to use the likes of Liverpool.

Going forward, GBRf warned in its application that removing this new biomass flow would mean there is no margin at all during the peak winter period, when the UK requires more energy, and thus a continued national supply would be at risk.

And it’s not just Drax that is spending money on this project. The Port of Liverpool is spending £350 million on the ‘Liverpool 2’ Project that will enable larger vessels to dock at the port. This sum also includes the enhancement of its own rail infrastructure, enabling it to better manage a predicted large step-change in intermodal and biomass traffic from this year. It is also planned that steel, scrap and car trains will form an integral part of the Port’s future business plan.

GBRf has also spent big on this scheme. It has invested in Tuebrook Sidings and bought brand new Class 66s that will be delivered early next year. New traincrew have also been recruited.

This represents a huge investment, and an example of GBRf’s ‘can do’ attitude. What it needs now is the industry and stakeholders to help support the growth of rail freight.

- This feature was published in RAIL 788 on November 25 2015

FrankH - 02/02/2016 11:35

Another route could be to Warrington BQ as now then WCML to Farington Jnct then the East Lancs line via copy pit into yorkshire rejoining the original route at Wakefield. Maybe longer mileage wise but there's not a lot of traffic uses the route.