When British Rail reopened a short section of line under central London in the 1980s, it radically changed the way many commuters reached their offices.

Snow Hill’s tunnels had been mouldering for around 15 years when BR’s newly created Network SouthEast sector realised the potential they held. Restoring the half-mile link between Farringdon and Blackfriars re-created a north-south route across London that had been lost in 1969, allowing BR to run through trains between Bedford and Brighton. These trains were Class 319s, with their dual-voltage capability able to work on the overhead electrified Midland Main Line and the third-rail road to Brighton.

Dubbed Thameslink, NSE reckoned in 1988 that the whole project would cost £54 million including the new trains (that’s £133m today, allowing for inflation). The project allowed Holborn Viaduct station to close, replaced by City Thameslink. Farringdon was once again a junction, with some trains heading southwards for Blackfriars and some turning east to serve Moorgate. Not restored was the south-to-east chord that had closed in 1927.

Fast forward just ten years from 1988 and there was plenty of talk about expanding Thameslink, this time with ‘2000’ tagged onto its name. This would expand NSE’s idea and add a link to the East Coast Main Line (ECML).

Such a link had existed until 1976, with direct trains running from the ECML into Moorgate via King’s Cross. BR shut this link and instead ran trains into its other Moorgate station (the Deep Tube one that had been served by London Underground until 1975).

Thameslink 2000 is today simply Thameslink, a £6.5 billion project that now has its finishing line in sight. New Class 700 trains are running and the huge list of engineering jobs is drawing to a close.

The project is divided into three stages, called ‘key outputs’. Key Output Zero (KO0) in 2009 closed the Moorgate branch, because Network Rail had to extend Farringdon’s platforms to enable 12-car trains to run, and it could only do this by taking the space used by the junction for Moorgate.

This stage also closed the terminal platforms at Blackfriars, ready for that station to be rebuilt to switch its terminal platforms from east of the through lines to the west. The station was also extended to span the River Thames, so that it can serve north and south banks.

KO1 turned the project’s attention to delivering the infrastructure needed to run 12-car trains between Bedford and Brighton. It built a new viaduct at Borough Market, which was finished in 2012 but which did not open until it was needed in 2016.

KO2 featured a further increase in engineering work, with track laid in Canal Tunnels between St Pancras and the ECML at Belle Isle. The tunnels themselves were built between 2004 and 2006, as part of the rebuilding of St Pancras station as the terminus for High Speed 1 and international trains from France and Belgium. This project also delivered a station box for Thameslink, which opened in 2007 and replaced nearby King’s Cross Thameslink.

KO2 also delivered a dive-under at Bermondsey, in south London, to allow Thameslink services to be separated from those of Southern and Southeastern. It is delivering a new station at London Bridge, in what is probably the most visible part of the whole project, as well as extensive changes to track and signalling in the surrounding area. There has also been work further from London, such as building stabling sidings at Peterborough.

Today’s project goes far beyond the comparatively simpler project that British Rail delivered. Simon Blanchflower is the man running it from offices in south London that overlook the tracks between London Bridge and Blackfriars. RAIL met him to talk about how such large projects are efficiently delivered, and he is clear that creating a realistic schedule and then sticking to it is vital to success.

“On Thameslink, we have several inter-related project streams that come together to deliver the overall outputs. We’re rebuilding London Bridge station using a series of sections across the station. We progressively move from south to north across the station, taking sections of the station out of use to rebuild them, bringing that back into use and then taking the next section out.

“That clearly has to align with all the track remodelling and the resignalling work that goes on in parallel. Each time you take a section of station out, you have to remodel the track layout to accommodate those changes. That has to be aligned with the signalling aspects that you’re going through. So actually, establishing an integrated staging schedule through that period was absolutely key.”

The schedule Blanchflower is talking about was set back in 2012, and included firebreaks to allow for events.

“It might mean that you have to deploy some contingencies and mitigations along the way so that you adhere to the programme, but that is small in comparison with the impact of not adhering to the staging strategy and having to rework and re-stage the sequence of works. For me, a key aspect of efficiency has to be a robust schedule, a robust staging strategy that everybody is aligned around and which gives focus to the programme team as they deliver the works.”

Of course, NR doesn’t do all the work itself. Most is delivered by contractors, and Blanchflower created a loose (rather than formal) alliance so that everyone’s efforts were unified. This meant that Costain (rebuilding London Bridge), Balfour Beatty (remodelling track) and Siemens (delivering revised signalling) all depended on one another.

Blanchflower notes: “Each of the supply chain members has a series of incentivised milestones that they have to achieve, but they only get rewarded if everybody achieves their milestones. So it brings that cross-fertilisation, that cross-alignment of incentivisation - they either all succeed together or they all fail together.

“That drives the behaviours around how those various supply chain members work together to achieve those delivery targets. You can have a schedule, which is great, but then you need a contractual mechanism and an alignment of values within a supply chain that’s going to mean that your key contractors are focused on achieving that schedule and supporting each other.”

However, having a schedule is not the same as having an efficient schedule - either in terms of time or money. Trying to do something too quickly, with high levels of concurrent and inter-dependent work, can raise the prospect of delays. But taking longer might involve higher costs in terms of contractor employment or disruption compensation.

Blanchflower contends: “Clearly there is a balance that needs to be struck between that loss of capacity and capability of the network, diminution of offer in terms of the ability to run train services, with the costs of the works you are carrying out.

“I think what we’ve tried to achieve through the staging strategy we have had at London Bridge is, as far as practicable, to get the right balance between disruption to the rail network and providing us with sufficient access to enable efficient delivery of the works.”

He’s honest enough to admit that he might not have always achieved that perfect balance, but reckons he’s reasonably close. Working out what that right balance might be involves talking to those affected.

“The Thameslink programme has had a fairly mature programme board for a number of years, which draws together the Department for Transport, Network Rail (both in terms of the route and the delivery programme), the key train operators, Siemens as the rolling stock manufacturer, and so on.

“There is an industry partners’ board that oversees this, so the maturity of the relationship between the various industry partners has helped us to work through a number of iterations that has brought us to a place where people are not necessarily entirely comfortable, but accepting that it provides the best balance in terms of optimising the schedule and access required to do the works.

“You could measure efficiency in terms of construction costs, but I think in this context you have to try to measure efficiency in terms of our broader basket of measures. This will include the cost of the project, the compensation to train services, the impact on the travelling public, the franchise return and so on. There are a number of measures that need to be brought together in terms of overall industry efficiency.”

This suggests that what’s efficient for one player might not be for another. For Thameslink, the DfT sits at the centre. It owns Network Rail and sets the specification for the train operator to work to. It usually does this through a franchise, but such were the risks surrounding Thameslink that it took the unusual decision to let the train operation as a deal in which the DfT receives all the fare revenue and pays the operator a fee for running the service. This means that if the project went badly wrong and trains could not run, it would not be the train operator that suffered from something that it could not control.

That’s not to say that the first plan was accepted as the best one. It bounced back and forward: “There was a feedback loop that said ‘this will work, but we don’t think we can live with this level of restriction in this part of the layout - can you relook at this part to try and lessen the impact on capacity?’ So you go back and look at the rework cycle to understand what that might look like in terms of programme duration and staging.

“Effectively, it is an iterative process that says that if you start to break this down any further then the extension to the programme is going to be significant, and therefore your construction costs are going to start to go up and so we really can’t go down that avenue any further. It is primarily through dialogue with subject matter experts, pulling together people from train operators, working through with them what can we do with the train service, how can we reorder the train service in order to be able to accommodate this.”

Assurance that the programme (as finally decided) is as good as it can be comes from its acceptance by other players. But it doesn’t always work, as the problems at London Bridge in January 2015 showed.

“We tried to run too many trains into London Bridge Low Level, and had to do some fairly short-term re-planning to try and re-optimise that,” admits Blanchflower.

“I think it just illustrates that when you have such a tight system that you’re operating in the London area, which we are - you can model it, you can do all the planning, but because of the inter-connected nature of a lot of these services and how the network operates as a system, sometimes even small discrepancies can start to have a wider impact, which is what we saw in January 2015.”

Or put another way, you can gather all the expert opinion you can find and still make the wrong decision. And by the time the next major project is looking for similar experience it will have dispersed, which makes tapping that knowledge harder. But even if your plan does work, it might not necessarily be efficient. You may have added more cost than was needed, or be running fewer services than could be run or be needed to run.

This sets Blanchflower thinking, and there’s a long pause. He orders his answer and then speaks carefully: “The key driver in the London area, where you’re talking about a commuter railway, is your ability to move passengers. And so maximising capacity, particularly at these times when you’re taking part of the network out of operation, is a good measure for efficiency.

“In terms of construction measures it’s your ability to maintain programmes, how much rework you need to do as a result of your delivery. So the quality of what you’re delivering, your ability to deliver within the budgets you’ve been set, your use of contingency - I think there are a number of measures you can pick up. But I’m not saying necessarily that all of this can be quantified to the nth degree. I think there still has to remain elements of qualitative assessment, simply because of the complex nature of the industry in which we’re operating.”

There is another factor that particularly affected Thameslink. That was the continued rise in passenger numbers even after the project built it plans back in 2012.

“When we first started planning the redevelopment of London Bridge we were talking about 37 million passengers per annum using the station. Today, we see well in excess of 50 million. So even some of the planning we did back in 2012, some of the underlying assumptions we made then, have been proved wrong simply by the increased growth in the network and the challenge that brings.”

Talking to Blanchflower about efficient project delivery, it’s increasingly clear that efficiency is almost whatever you want it to be. Becoming more efficient in one area leads to reductions elsewhere. The wider you cast your net the harder the problem becomes. At one extreme, it would have been much cheaper and quicker to build Thameslink with the railway completely closed to passengers. But other than long Bank Holiday weekends and Christmas periods, complete closure was never a realistic option.

That left Thameslink looking for ways to make individual parts of the project efficient within themselves, while still running sufficient trains for passengers. This is more easily done for repeatable tasks than for one-off jobs - if you’re a track gang charged with relaying 800 metres every night, then with practice you’ll become quicker or you’ll be able to lay more track for the same time.

According to Blanchflower: “When you’re delivering a major enhancements scheme, it’s not as if it’s something that’s replicable in that sense, and you can measure a true efficiency through that.

“What we can measure is that as we move across London Bridge station from south to north, the cycle time for constructing each of the bridge decks, platforms and so on has reduced during the progression of the programme. Something that was taking us nine months to do initially, we’re now doing in six months.

“There’s an inbuilt efficiency there within the delivery of the programme. As we have progressed through it we have better understood the logistics around the site and how we can progress through the cycle of demolition, foundations and column erection, bridge deck erection, platforms and so on that has led to a delivery efficiency.”

Efficiency can come from building in lower long-term costs, by making maintenance easier. Thameslink’s project director offers this view: “If you look historically at signalling schemes, they would have a lot of location cases distributed along the railway which hold the signalling equipment. We made decisions very early on that in terms of both future access and maintenance, but also in terms of quality of build, it would be far better to install a number of REBs , so we found a number of arches along the route where we’ve installed these REBs. You can get them pre-wired in the factory, pre-checked in the factory, and delivered to site.

“It’s efficient for us in terms of delivery and quality of work, and it drives efficiency into the ongoing maintenance and operation of the railway because the maintenance staff can do a lot of their faulting and testing out of the direct railway environment by going into the REB off-track. You can see a number of efficiencies we’re delivering in that respect.”

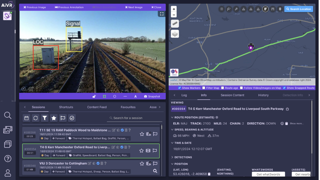

This pre-fabrication in signalling extended to the automatic train operation (ATO) system that Thameslink will use. Much of its development took place in a laboratory at Hitchin, with trains tested nearby on a short section of the Hertford Loop while normal trains continued to run on an adjacent track.

By the time the first Class 700 arrived from Siemens, the project had completed 80% of the testing it needed. Using the loop’s test line with the ‘700s’ meant that only the final 10% of tests needed to take place on Thameslink’s core route under London, vastly reducing the disruption passengers might face.

Bermondsey dive-under used a great deal of pre-fabricated concrete. Pieces could be cast in factories to a better quality than could be done on site.

Blanchflower explains: “You get a very good-quality product. Another interesting one on Bermondsey is that because we were demolishing a lot of the Victorian arches to create the space to build the new dive-under, we retained some the piers from the original arches to use as foundations for the new concrete arches for the new viaduct. That avoided us having to sink new foundations, and do a lot of time-consuming groundworks that would potentially be quite costly depending on what you find below ground. Re-using those foundations made for a far more efficient delivery.”

This re-use wasn’t initially expected. Says Blanchflower: “When we went through the detailed design with Skanska, the opportunity presented itself. And when we looked at the suitability of those arches - the strength within them, whether they could be used for that purpose - it was evident that they could be built into the design.

“The Victorians usually got it right in terms of arch spacing, and so even when you’re looking at putting a concrete arch on an old brick foundation, the dimensions are pretty much the same.”

The cost of not installing something properly first time can be considerable. “Looking back historically, we’ve found that the cost of putting things right or the cost of prolongation can be six, eight, ten times higher than doing it right first time and on schedule - simply because of access constraints, rework cycles, and the inefficiency of delivery when you’re coming back and doing things a second time or not in the sequence you originally envisaged.”

But delays don’t just come from fixing poor installation, they can also come from external stakeholders - for example, train operators unhappy with the cuts their service could suffer, or local residents unhappy with potential noise from night-time work.

“Stakeholders can either be very supportive of what you’re trying to do or they can, if you don’t have them engaged, act as blockers,” reckons Blanchflower.

“If you have a key stakeholder that’s acting as a blocker in any respect, it is likely to drive inefficiency into what you’re doing simply because of the effort you need to apply to re-engage with that stakeholder - their potential to frustrate access, their potential to frustrate station or network change or industry processes.”

Thameslink has faced most of the challenges any major project could face, giving Blanchflower a good perspective across the wider network.

“You get into this cycle of the more the network is used, the more it needs to be maintained and renewed, and the more access you need. Somehow, we have to find the right balance as an industry between access availability and the offer we make in terms of train paths. That’s going to be one of our key challenges going forward as an industry, to make sure we keep the right balance there.

“London Underground is facing that at the moment, as it moves towards 24-hour operations at weekends on many of its lines. You then have to work out how to fit in the maintenance and inspection activity that you need to do within the remaining five nights of the week.

“There was a piece of work I was involved with a couple of years ago which was about getting the right balance between running trains and having time for access to do maintenance and inspection work.

“We identified that a train on a Monday, Tuesday and Wednesday night was more lightly loaded than a late-evening train on a Thursday or Friday night. You can more easily cancel the last couple of trains on a Monday, Tuesday or Wednesday night, but allow the operator to run more trains on a Thursday or Friday night when the demand is there.

“Therefore, you can give longer periods of access Monday, Tuesday or Wednesday nights, which means the maintainer can get more efficient work done because they have a longer window to do that work. They can do that then, and not worry about rostering people on Thursday and Friday nights when the window is much smaller and the inefficiencies of delivering that work are much greater.

“We have to continue as an industry to work those algorithms. Obviously, freight trains need to work into that, because a lot of freight runs overnight. But as an industry we need to continue to work these things - that’s the whole role of RDG at the end of the day. It’s RDG as the industry leader that should work these issues, to try to find the most efficient way of maintaining and operating this network.”

Thameslink should be finished next year. It will transform rail services across London’s north-south axis just as British Rail’s initial project did in the 1980s. Up to 24 trains per hour will run through the central core, linking Peterborough, Cambridge and Bedford in the north with Brighton, Wimbledon, Horsham, Maidstone, Rainham, Sevenoaks and Orpington in the south (and Littlehampton and East Grinstead at peak times).

Once the trains are running, it’s vital that the wider railway industry extracts every last bit of experience from the project team. They have learned valuable lessons that can help Britain’s railway continue expanding.

This feature was published in RAIL 828 on 3rd June 2017

Login to comment

Comments

No comments have been made yet.