More than 80 wagons across the UK retrofitted with digital technology that monitors performance and identifies faults will be in service by the end of the year.

More than 80 wagons across the UK retrofitted with digital technology that monitors performance and identifies faults will be in service by the end of the year.

All 32 JGA wagons operated by Heidelberg Materials have now become “iWagons”, with Alvance to receive 20 of the same type and Tarmac having 30 JGA-M wagons. All projects are set to be completed by the end of the year.

Meanwhile another 89 brand new JPA iWagons are due to be delivered next year; 54 for Breedon and 35 for Heidelberg.

The Heidelberg work was carried out at its Ribblesdale Cement Works in Clitheroe and Padeswood Works in North Wales, where 17 and 14 wagons were fitted respectively. One had already been fitted as part a trial.

Archie Lucas, VTG Rail UK Sales Manager, expressed his pride over the achievement: “It is fantastic news that the entire fleet of Heidelberg JPA wagons have now been successfully equipped with VTG’s iWagon technology. iWagon will serve the rail freight industry through improved safety and reliability, so it is a landmark event for VTG and the industry.”

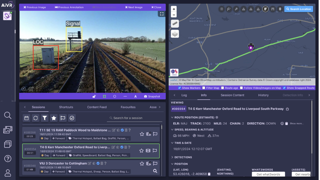

iWagons include wheel slide technology that can identify if a wagon’s axle has locked and attempt to get it turning again (which can prevent wheel flats and reduce track damage), as well as brake condition monitoring and other-real-time data.

All wagons fitted are owned by VTG Rail UK with the equipment provided by Knorr-Bremse. VTG is in advanced discussions for up to 1,000 more iWagons to be operating on the network during 2026, made up of both new-build and retrofitted vehicles.

“If we get data saying there’s a potential issue, we can build up a picture and spot trends,” explained Knorr-Bremse Business Manager, Joshua Jordan-Boddey.

During trials, which started in late 2023, the technology picked up problems within days of being fitted, such as a 0.5-km (0.3-mile) double axle lock on a train at Laurencekirk, between Aberdeen and Dundee.

While this technology has been around for many years, it’s been concentrated on passenger rolling stock.

Nine cement wagons operating in locations such as Dunbar and Clitheroe were fitted with the equipment during a trial in 2023/24.

These ran across three rakes, each containing two that were just recording data and one that had the wheel-slide technology.

Jordan-Boddey said Knorr-Bremse had been working to “understand if the prototype gives information people want”, adding: “The biggest goal is going from that to final product in a short time while developing the digital platforms.”

Login to continue reading

Or register with RAIL to keep up-to-date with the latest news, insight and opinion.

Login to comment

Comments

No comments have been made yet.