A major milestone has been achieved in the construction of HS2 as the completion of the first viaduct at the Delta Junction in North Warwickshire has been completed.

A major milestone has been achieved in the construction of HS2 as the completion of the first viaduct at the Delta Junction in North Warwickshire has been completed.

The 472-metre-long single-track Tame West Viaduct marks a significant step forward in the project as work intensifies in the region. Delta Junction itself is a key part of the HS2 project as the location where the track splits off towards Curzon Street whilst also heading north towards Staffordshire.

HS2 has been slowly building the huge viaducts which will form the structure for the high-speed line to line to run on, with the single track Tame West Viaduct sitting just south of the Curdworth Box, where the up line splits.

Sam Hinkley, Lead Senior Project Manager for Delta Junction at HS2 Ltd, expressed his pride in the progress, stating, “The completion of the River Tame West single-track viaduct is a significant achievement for the Delta Junction team. This challenging area is home to some of the most complex engineering in the country. It’s the result of the hard work of nearly 10,000 people across the West Midlands, who are contributing to this world-class engineering effort that will lay the foundation for the UK’s future rail network.”

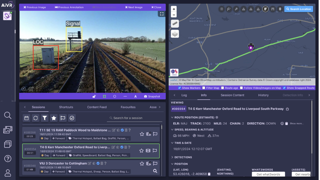

To complete the first viaduct, HS2’s contractor in the Midlands, Balfour Beatty VINCI, has deployed a giant cantilever structure to build the span segment by segment. The technique has never before been used in the UK.

The work, which began in 2023 with the construction of the viaduct’s piers, saw the concrete deck build-up commence in early 2024. Since then, a total of 190 pre-cast concrete segments have been successfully installed, a crucial step toward completing the structure. Once finished, the River Tame West Viaduct will be part of a three-track system, which will also include a double-track viaduct that is now under construction.

The junction will include 13 viaducts spanning over 8 miles, supporting the railway’s passage over rivers, existing rail lines, roads, and motorways.

In addition to the River Tame West Viaduct, the River Tame East Viaduct is also under construction in the area. The Delta Junction site is considered one of the most complex sections of the HS2 line, with two Water Orton Viaducts being built alongside the River Tame structures.

The specialist cantilever technique, which is being used for nine of the 13 viaducts at Delta Junction, has been instrumental in constructing the pre-cast segmental viaducts. This method involves the use of a mast, swivel crane, and cable stays to position the concrete segments. The segments are pre-cast at HS2’s nearby factory in Lea Marston, and the process allows for rapid and precise placement, ensuring structural integrity and minimising disruption.

“This is the first time we’ve used this innovative technique in the UK,” said Nicolas Gallone, Pre-cast Segmental Viaducts Project Manager at Balfour Beatty VINCI. “It’s an efficient and flexible process, and a great achievement for the whole team. We’re now continuing with this technique on the other viaducts in the Delta Junction area.”

Login to continue reading

Or register with RAIL to keep up-to-date with the latest news, insight and opinion.

Login to comment

Comments

No comments have been made yet.