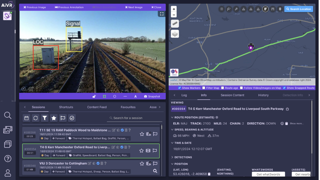

Watch the Dawlish Sea Wall cab ride video.

Up until 0200 on April 4, Network Rail was unsure when the line through Dawlish would actually re-open.

That would have been a major stumbling block, as that was the day Prime Minister David Cameron was due to visit the Devon town to officially re-open the line that had been washed away two months earlier.

NR’s new Chief Executive Mark Carne, only a few days into the job, was to accompany Cameron and greet members of NR’s ‘Orange Army’, who had completed the repairs.

But there had been further damage along the exposed sea wall route. The wall itself was repaired sufficiently for trains to pass, but the condition of the cliffs near Teignmouth was now causing complications.

So that morning NR staff, including press officer Julian Burnell, were out walking the line to see if it was passable. Thankfully it was.

The story of what happened at Dawlish is well known (RAIL 742-746, 759). One of the biggest storms to ever hit the South West peninsula struck the resort, causing devastation. The weather had actually turned a few days previously, with a small washout on February 2, but that was not enough to cause major damage. The big storm followed two days later!

Burnell says that the team watching for the weather had never seen such a severe warning. “It was code black, they couldn’t believe it.” (Code black is the highest warning for a storm - NR had never received one before.)

And he recalls the situation that confronted him when he arrived at the scene the following morning. It sums up Dawlish perfectly.

“When I got here it was beautiful. But then I realised I was looking across at the Down platform, and there were waves splashing through. The Down platform had been destroyed by the waves, with most of it on the track.”

Initially, one of the major challenges was to render the area safe. The beach was still open (in fact, NR has never been able to officially close it), which meant that on the following day there were plenty of sightseers visiting the beach, walking up to the damage site to take pictures of the track dangling in mid-air. RAIL published some of them.

“We had problems with people looking at photographs that had been taken, and wanting to take their own,” says Burnell. “Riviera Terrace was not happy with the number of sightseers.”

But NR’s priority was on getting more than just the beach safe, it needed to make the whole area safe.

“We had people on the beach, but we had to get the houses next to the railway safe, too,” says Burnell. “The houses were at risk, and one was actually undercut by the damage. We had to put monitoring systems in straightaway, because the area had to be safe.”

Teignbridge Council, the local authority, quickly employed a security firm to deal with the problem. NR subsequently also employed the company, because of the distinct need for public management.

Not only did the company need to start repairs, there was also a lot of debris that could have endangered public safety. Rocks and bricks were strewn across the beach, as were parts of Dawlish railway station!

Says Burnell: “It was a four-mile stretch that was closed. If you walked to it from Dawlish, you would keep finding bits of wall.”

The popular walkway along the wall was also closed (some of it still is). Public access could not be granted until it was safe.

“People do not understand the force of a big wave. It is frightening. It isn’t like anything else,” says Burnell.

The entire walkway has since been repaired with replacement stones, capping and general repairs where needed.

One of the first tasks was to remove the track that was dangling from the 80-metre hole in the sea wall, although Burnell says: “In actual fact, it made you think: ‘How tough are our welds?’ The track was hanging there, getting hammered by the sea, and they were holding.”

Even so, the problem of hanging track clearly had to be resolved.

Says Burnell: “We chopped the tracks down. One went onto the walkway to try and give stability, and the other was on the side of the slip for the same reason. It helped for a little bit afterwards.”

Because of the location of the railway through Dawlish, NR is often told there are problems that subsequently turn out to be not as severe as perhaps initially reported. This can sometimes lead to scepticism.

Says Burnell: “Because it is so exposed, the initial reaction is ‘it’s Dawlish’. But we have a specific repair team, and we have systems in place to deal with problems.”

He then surprises RAIL: “In many ways we were very, very lucky.”

How can NR have been lucky?

“People got calls about the wall, and just got going. There was no haggling over deals, it just happened.”

That teams were already at a possession at Whiteball Tunnel (between Tiverton and Taunton) was also fortunate. That project was concluding, with the railway set to re-open. A lot of the required equipment was therefore already close at hand, including a concrete machine that meant the wall could be sprayed with concrete. While no structural work could be done immediately, that would at least offer some protection.

Glynn Eley is Project Manager for Network Rail, the main contractor at the Dawlish Warren compound where the repair work is based these days. He explains that problems continue to be encountered regarding the repairs.

“We were not allowed to work on the beach,” he says. “We could not do test anchors for the wall, as we couldn’t drill down.”

He says the multi-coloured containers that are on site have certainly proven their worth. Battered, bruised and dented, they acted as another line of defence for the wall when the second round of storms hit.

They were delivered to Dawlish Warren on February 7. Road/railers were used to transport them to the site, a 21-tonne excavator was positioned to assist, and by low tide they were in place, loaded with up to five tonnes of ballast made up from what was left of that section of the sea wall. The work took 36 hours to complete.

Again NR was lucky, because the way the wall collapsed meant that the debris wasn’t scattered, but condensed in one area.

Eley recalls: “When I first arrived at the site there was a big hole. The track had been picked up and it was spray concreted. That saved the undercut house.”

Repairs are ongoing 24 hours a day. But the location is “tricky”, Eley admits. The tides create a problem. And then there is the wind to contend with. The southeasterly winds are the worst because they drive the waves against the wall (it was from this direction that the destructive waves of February 4 came).

It’s not even winter yet, and the waves have already caused problems for the repair team. Equipment has been damaged, while some buoys that were moored just off the site have been cut free and floated away.

When RAIL visited on October 2, Eley’s team were preparing suitability anchors, so that work can then progress on rebuilding the wall. It was being checked up to 27 metres in front of the containers. The problem is that there is not enough rock to drill into of sufficient quality.

“Currently there is rail at the top, and then AMCO is putting in a levelling screen at the low level. Then units will go into this, which will be anchored into the rock, and then we will backfill,” says Eley.

Ballast on the trackbed has been glued, having already been tamped. This means it is solid and shouldn’t move, even in the event of another storm. The entire wall hasn’t been treated, just the sections where waves are known to come over. Burnell says that there have yet to be any problems.

So when should the project be finished?

Says Eley: “When we started out it was ‘get it done as soon as possible’. Then it was ‘get it done by February’. But there are problems, such as finding the rocks. The project has been delayed. Possibly we may have to use revised methodology, so it is drifting to possibly March or April. The other problem is that you just cannot tell with the weather.”

Amco and NR use MeteoGroup for forecasting, but other sources can also be used. However, what is expected or predicted isn’t necessarily what happens, as RAIL’s visit illustrated.

The tide was due to be at its lowest at 1800. That’s when RAIL visited the site, only to find a southeasterly wind blowing the waves against the wall. The tide therefore didn’t go that far out, certainly not enough to enable access to the worksite. And this is September - when the winter storms hit, the delays could be much more prolonged.

“The weather window is the biggest challenge,” says Eley.

Recently, a barge appeared at Dawlish. This is used to transport materials to the site, otherwise they would have to come by rail, which Eley says would create massive problems.

The barge holds six pre-cast units, and Eley says that if Amco has a “good spell”, then over a 24-hour period they can all be installed in the wall. In total 164 units are to be fitted, each weighing 15 tonnes, with deliveries due to start as this issue of RAIL went to press. This means that the tide will cause fewer problems. The barge is served by tugs that arrive from nearby Teignmouth Docks.

A 250t crane is also located on the barge, and there is an option for a second barge to arrive if required. But they do not come cheap.

“The likelihood is that it will be here until January, says Eley. “There’s an alternative method of holding the units in place that will, in turn, hold the rock anchors. We’d like to finish by Christmas.”

Today there are around 30 people working on the repairs - at the project’s height there were 350 to 400.

“We were getting people from where we could,” says Burnell. “We also sucked up concrete supplies until the autumn.”

Most of the workers who were here at the start have now left, although a few remain.

Eley enthuses: “It is amazing. I should have retired. I’m seconded to Network Rail. I wanted to finish my career on it. I have never seen such collaborative work in my 45-year career. It has been brilliant.”

How did he get involved?

“I had just finished an accident and emergency department at Taunton. We were then called in.”

Another who has been at Dawlish almost from the start is AMCO Rail’s Chris Warburton, one of the ‘Great Westerners’ who appeared on YouTube (RAIL 759).

“I first met him as he climbed out of the hole at Dawlish,” says Burnell. “There had been waves and rain, and he was the epitome of the phrase ‘drowned rat’.”

Warburton is described as a character. He makes jokes, but is straight and to the point when discussing his work.

“As a job it has been a challenge. It’s been a great team-building exercise, eventful on every level and good to bad at times.

“I came from Essex as construction manager. I volunteered for the weekend and am still here. I love emergencies. I was the shift manager for night shifts, and once we got the situation controlled I reverted to days.”

Despite being a manager, Warburton says he still likes to get his hands dirty working. And working on the wall was new for him.

“I didn’t know anything about the sea. I understand tides now. It was a vertical learning curve. It was civils in a rail environment. Marine is not as regulated as rail.

“One problem was that I didn’t know anyone. But it is a task you have to deal with, because you have to fill the hole. The best thing we did was bring in non-PTS operatives.”

He says this is because for many of the railway staff the marine world was new, and so staff were far more careful. “We did 53 days with two incidents. I believe the extra care was there.”

Warburton has been at Dawlish so long he has a long-standing booking at a hotel near Dawlish Warren - the owners even invited him to their granddaughter’s wedding. He travels home every other weekend (when he can) to see his children.

He says his role now is “doing logistics, project manager, operations and designing management for the works for the rebuilding of the sea wall”. He has even undergone training for working on a barge, which has included life-jacket training, although: “You don’t have to swim to work here, because you are hooked on to the sea wall.”

But he loves it in Dawlish: “There’s lots of people who you would never meet. The craic here is brilliant.”

And he says that helps the team: “At the moment it’s long, stressful days. It is backs against the wall. When you stand back there is a sense of pride.”

Warburton tells RAIL that the work has to move much faster than usual.

“You would go through the GRIP stages normally in 18 months. That process has had to be done in 18 hours at times, and we are still reacting to things. We are working 24 hours a day, and yet have to rely on desktop studies and so people are trying to keep up.”

He remembers April 4 well. “I watched the first train, shaking, to make sure it was OK.”

What does he think of this job?

“It brings out the best in guys. I hate planned jobs. Some people don’t like changes, but I want the pressure. And it is still like that. It is still changing. For instance, while we have designed everything, we don’t know what is under the wall.

“But we will be out there. We will do what we physically can. The guys here will do that.”

His attitude encapsulates exactly why Network Rail was awarded the Judges’ Special ‘Orange Army’ award. It is richly deserved.

- This feature was published in RAIL 760 on 29 October 2014

Chris Gooding - 27/09/2018 22:02

It would still be beneficial to reopen the old LSWR line via Okehampton and Tavistock.. It will happen again and the people in and around Devon and Cornwall stranded.. costing the Government Billions in lost revenue. Reopening this line will help businesses grow. Aid traffic issues in and out of Plymouth towards Tavistock. Finally a diversionary route if this sea defences fail again in which it will. Not maybe. Having a circular route with 3 trains running each way would give a half hr service for locals into and out of Exeter and Plymouth. Great for commuter also for tourism.. Still have your cross country services and GWR keep there services. Rail Infrastructure for the south west needs a revamp it is falling so far behind the rest of the UK. re dueling the Salisbury to Exeter line. extending the electrification programme to Exeter via Bristol and the Reading to Taunton line. This is what the south west needs.. good fast rail system to Bristol and to the Capital.