A high proportion of existing high speed tracks have been constructed using ballast. Several such systems have now been in operation for many years, including ballasted high-speed tracks in Belgium (SNCB), France (SNCF), Germany (DB), China (MOR) and parts of the network in Japan (CJR/EJR/WJR).

PROS: The resilience provided by the ballast, the possibility of track realignment, effective drainage and low initial construction cost are all attractive features of ballasted systems.

CONS: But, as on most tracks, differential settlement in the ballast layer means that regular tamping may be required to maintain track quality. This is exacerbated as train speeds increase, pushing wheel-rail contact forces higher, and therefore a means of reducing the dynamic forces transmitted into the sleepers and the substrate becomes more important and attractive.

Ballasted track stability

Providing resilience in the rail fastening system on top of the sleeper and the use of resilient pads under the sleeper can reduce overall track stiffness, distribute vertical track loads, and attenuate the dynamic forces transmitted into the ballast.

This can lead to lower rates of track degradation and therefore longer maintenance intervals. Providing a means of improving track stability and ballast life should be one of the key targets for HS2, if ballasted track is used. One of the project’s aims is for a low maintenance railway, which is essential to deliver the desired 18 trains per hour at speeds of up to 224mph (360kph).

PROS: As well as lowering track stiffness, the use of under sleeper pads (USP) increases the effective bearing surface of the sleeper, bringing more ballast into play and providing more support to the sleeper. This reduces contact stresses and increases ballast life and maintenance intervals.

CONS: Introducing resilience above and below the sleeper are not equivalents - they have different effects on the dynamics of the track system, and the stiffness levels of both elements need to be chosen with care to work together, rather than against each other.

High-resilience fasteners with ballasted track

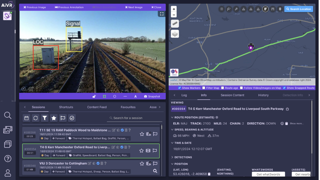

Resilient fastenings are most commonly associated with non-ballasted track and can be introduced with different levels of resilience in the concrete sleepers through the rail pad material and shape. Where additional resilience may be required, a higher performance system can be provided on top of sleepers in ballasted track. During a trial installation of the Pandrol VIPA DFC system on concrete sleepers on a section of French SNCF main line track, measurements show a marked decrease in vibration transferred from the wheel rail interface to the sleeper. Loads transmitted into the ballast and substrates are therefore also reduced

Resilient fasteners with non-ballasted track

Pandrol has been supplying resilient fastening systems for non-ballasted tracks for more than 40 years, from the early Shinkansen tracks in Japan to the more recent South Korean and Chinese high speed systems.

Both rail systems have been successfully operating with track fastenings that are incorporated into different basic forms of slab, including on track panels and individual pre-cast concrete sleepers. The most important factors in selecting the variant required for any given application are the means of track construction and the requirements on range and ease of adjustment.

Typically, the Pandrol VIPA DFC assembly shown (left) is well-suited to high speed applications installed on pre-cast blocks, sleepers or slab.

- This feature was published in the HS2 supplement of RAIL 789 (December 9 2015)

Mr Stephen Brownrigg - 16/12/2019 08:18

Thanks for the info, I'll be using some of it towards my level 3 diploma in rail engineering and technology.