Nine years ago, Cemex opened a small pop-up yard next to the West Coast Main Line at Warrington. It wasn’t expected to last long.

“We were looking at opening somewhere fairly quickly,” recalls the company’s Rail and Sea Manager, Mark Grimshaw-Smith.

Nine years ago, Cemex opened a small pop-up yard next to the West Coast Main Line at Warrington. It wasn’t expected to last long.

“We were looking at opening somewhere fairly quickly,” recalls the company’s Rail and Sea Manager, Mark Grimshaw-Smith.

“That was about the time of the Mersey Gateway Bridge development. There was quite a lot of activity at that time - not just the bridge, but the surrounding area. Hence the pop-up.

“We ran our first train four or five weeks later.”

Fast forward to April 28 this year, and Cemex and DB Cargo have just celebrated moving one million tonnes of limestone from Dove Holes Quarry (near Buxton) to the Dallam Freight Depot at Warrington.

Approximately 200,000 tonnes is transported this way each year, with material used for projects such as the Omega West Business Park to the west of Warrington.

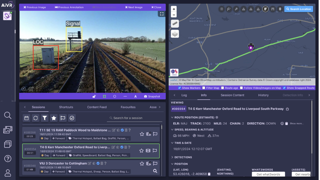

RAIL was invited to ride on one of the trains that runs at least twice a week, joining the 1418 from Peak Forest Cemex Sidings that starts its journey on the former Midland Railway main line between Manchester and Derby.

Loaded trains are drawn out of the Cemex sidings by a Class 66 hired by Victa Railfreight, which manages the aggregates firm’s yard. On the day in question, 66205 brought 23 loaded box wagons out, ready for our train engine (66139) to emerge from DB Cargo’s sidings and attach to the other end.

Getting one of these trains moving from a standing start is no easy task. Not only are they often around 2,500 tonnes (2,440 in this case), but it’s also up a 1-in-90 gradient which continues until level with Cemex’s loading area.

No wonder that despite dry rails and sand laid by the driver, as he rolled down to couple up to the train, 66139 is struggling to do more than 3mph as we pass the former Peak Forest station (now DBC’s crew depot).

Cemex wants to have 25-wagon trains running out of Dove Holes, which would be even heavier to get going. The current maximum is 24. It’s also working with DBC to extend the latter’s sidings on the western side of the line, to accommodate longer trains in future, thereby increasing the capacity for turning around services coming out of the sidings before reversing to continue with their journeys.

But that 3mph past Cemex prompts another hoped-for change. “Part of the initiative for moving from 24 to 25 wagons is having Class 66/6s,” explains Grimshaw-Smith. DBC currently has ten of these locomotives that have been regeared to increase haulage capability, making starts such as this slightly less difficult.

Class 66/6s have a lower top speed of 60mph (compared with 75mph of those with higher gear settings). However, trains such as those going to Dallam are only permitted to reach 60mph anyway.

Once past Cemex’s sidings it’s downhill for the best part of 15 miles until Northenden Junction. First up is the 1.7-mile-long Dove Holes tunnel—a structure which can be prone to flooding if there’s heavy rainfall in the area.

Such closures are a problem for the companies based along the freight-only Great Rocks Line, as it prevents a large amount of their material from getting out to construction firms.

Today, despite some morning rain, it’s OK, although the wipers are needed to clear the water falling from the roof.

We coast down the grade towards the Chapel Milton viaducts, two neighbouring structures that carry freight trains either west or east onto the Hope Valley Line. The viaduct used by services heading towards Manchester is due to be closed for nine days from August 29-September 7 for repairs.

As a result, trains bound for the likes of Dallam will be top-and-tailed as they traverse the viaduct that would normally take trains east, before reversing by Chinley East Junction to head west.

On this occasion there is a workaround. But as Grimshaw-Smith points out, when lines do close on Cemex freight routes, there’s no replacement fleet of lorries to move material in the same way coaches are provided for passengers.

As expected, our train is held before joining the Hope Valley Line at Chinley North Junction.

After a 12-minute wait, the signal turns to yellow, although we don’t move until it’s green. Our driver knows that moving on a yellow here will result in having to stop at the next signal, so waiting a few extra seconds for a green is faster in the long run – and more efficient as we only have to accelerate once.

Once on the Hope Valley, the first section of running that is close to the flow’s top speed of 60mph can commence. It’s just one of three such sections on the 55-mile route, with the others being Knutsford to Greenbank and Hartford Junction to Warrington Bank Quay.

The train then slows for the 3,867-yard Disley Tunnel.

On our approach to the exit, a message comes from the signaller saying to watch out for trespassers, following reports of someone running out in front of an earlier train. Despite a green, we proceed as if at caution, looking out for any trespassers, but none appear.

By now, we’re on the edge of Manchester, where passenger services turn right towards Hazel Grove station.

Our train continues along the largely straight freight-only line (very much a ‘green tunnel’) that skirts round the south of Stockport to reach Northenden Junction on the Mid-Cheshire Line, linking Manchester and Chester.

It’s along here that we pass another disused rail freight line – it’s still connected to an aggregates site, but heavily overgrown and not in a usable condition.

Grimshaw-Smith has previously spoken about the cost of reconnecting such sites, which would be used two or three times a week.

“You’re not going to spend £10 million on a connection. If you can do it for around £500,000, that would straightaway open up quite a lot of opportunities,” he says.

“There’s probably quite a few sites where you could justify it.”

Passing Navigation Road and Altrincham stations, our train is heading south by this point.

Just after Hale we pass an unusually angled twin-portal bridge under Ashley Road, before reaching open countryside as we head towards Knutsford.

Hale to Greenbank, shortly before the junction with the West Coast Main Line, is one of the quickest sections of the journey.

One thing the route between Peak Forest and Hartford Junction also has is a continuous stream of signal boxes. The last one of these we pass is at Greenbank station, shortly before the turn north onto the WCML.

After a wait of approximately 15 minutes at Hartford Junction, the last stretch along the WCML is a relatively easy, flat run at top speed, before slowing to enter Dallam Freight Depot (around one mile north of Warrington Bank Quay station).

The train crosses over to the Up side, before entering the former Royal Mail terminal.

Despite some instances of being as much as 20 minutes late, today a kind timetable means arrival in Warrington is two minutes early, at 1708.

From there, the train is set back towards the four-road yard. On this occasion, it’s divided up into four portions.

The rear four wagons (containing 4/20mm graded limestone) are left in road three, where ground staff immediately start unloading into a dedicated bay.

The next eight, also carrying (4/20mm), are put in road one for unloading later, while a further eight wagons (carrying MOT general purpose limestone) are put into road four.

The three wagons nearest the locomotive (carrying Type 1 MOT typically used as a sub-base for roads) are then put into road three in front of the four already being unloaded. MOT will be unloaded and left in the middle of the yard.

The terminal is not ideally set up such work. Roads one-three are between the yard and the WCML, and only wagons beyond a certain point can be unloaded owing to the proximity of overhead line equipment.

Line four is on the opposite side of the terminal, meaning road transport must cross it before reaching the unloaded limestone. Finer material is put into bays while MOT is left in a pile in the middle.

Cemex and DBC want to make changes to the yard, but acknowledge that’s something that can only be done at the start of a new five- to six-year operational contract.

“The right time to do it is at the start of a contract. You then have time to get your investment back,” explains Grimshaw-Smith.

“We’ve got a couple of ideas. Having 25 wagons helps everybody. We want to reconfigure the yard. If you are building from scratch, you would not have a line across the middle (road four).

“You would have more bays. You would normally have enough room for gravel, then bays all the way along (for different grades of limestone).”

Nine years after being set up as a ‘pop-up’ site, the Dallam terminal in Warrington is now a key part of Cemex’s rail freight strategy – with ambitions for more to come.

Login to continue reading

Or register with RAIL to keep up-to-date with the latest news, insight and opinion.

Login to comment

Comments

No comments have been made yet.