Northern’s principal maintenance depot has a rich history, and is playing its part in the railway’s future as well. Paul Bigland is given an extensive tour.

In this article:

Northern’s principal maintenance depot has a rich history, and is playing its part in the railway’s future as well. Paul Bigland is given an extensive tour.

In this article:

- Newton Heath Traincare Centre blends rich railway heritage with cutting-edge maintenance, including state-of-the-art Class 195 facilities.

- The depot features advanced jacking systems, remote-controlled shunters, and historic structures like the restored L&Y war memorial.

- Once threatened with closure, the site now thrives with modern upgrades and ex-forces personnel finding new careers there.

Newton Heath Traincare Centre is Northern Trains’ premier maintenance depot in the North West, and the site has a long and fascinating railway and social history.

The current site contains several buildings. The oldest features the remains of the steam shed, and the most modern is St Marys, built to house the Class 195 fleet. There are also classrooms and office accommodation, production offices, and stores.

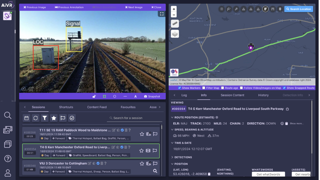

Adjacent to the main line and the fuelling apron is accommodation for the depot cleaners, as well as the ‘South Cabin’, which controls movements on and off the depot as well as around the site. A boiler house and three-cylinder fuel tank farm complete the picture.

The present

Movements around the depot are complex, but they can be summarised thus: When vehicles arrive on shed, they’re taken onto the fuelling line and through the wash plant. Vehicles that are due exams or that need minor repairs are then shunted around the site to the appropriate location. If they just require stabling, they’re allocated to the appropriate sidings, which are through roads parallel to the fuelling line of one of the five shorter dead-end roads adjacent to the Metrolink line to Oldham.

Maintenance and exams of the older BR built fleets is carried out in the legacy building, which has four through roads, while the adjacent ‘Parlour’ has three which are dead end.

On the north side a two-road shed (formerly the locomotive fuelling and inspection shed, and latterly the paint shop) contains a double-headed wheel lathe and a separate underframe washing plant.

The wheel lathe was originally installed at the Heathrow Express depot at Old Oak Common. When this depot was demolished to make way for Crossrail in 2018, the lathe was removed and stored before being installed at Newton Heath in 2020.

The lathe has its own remote-controlled Niteq 5000E shunting engine, named Bobby after a long-standing member of staff. And it has proved invaluable, especially during the leaf-fall season, as it means that trains no longer have to be sent across the Pennines to Neville Hill (Leeds) or Heaton (Newcastle), or to Allerton (Merseyside).

During my visit, fitters were busy in the old shed working on a Class 150 which had been stopped for Ultrasonic Axle Testing (UAT), a regular part of the maintenance cycle. A sister unit had several people checking and adjusting the engine timing.

As well as pit roads, road 6 is equipped with ten-tonne ‘Eurogamma’ jacks which can be used to lift vehicles off their bogies.

Outside on road 7, a jib crane has been installed to allow removal of particularly heavy equipment. which can then be taken away by lorry for servicing.

The Manchester end of the shed was previously used for C4 overhauls, but the work has been transferred to Leeds Neville Hill while the depot’s roof undergoes major refurbishment works (being carried out by GallifordTry).

This has entailed blocking off roads 4 and 5, which are used for storage of equipment, while the apron outside is required for roof access and loading of materials. Movement of materials and equipment adds another complication to depot life, as various roads need blocking when access is required.

To the south, a shorter shed forms the ‘Parlour’. The age of the building is evident from the tapered, round iron columns and wooden beams which hold up the roof, plus the brick exterior wall.

The ‘Parlour’ is also graced by a significant and historic feature. The Lancashire and Yorkshire’s carriage and wagon department created a war memorial to immortalise their 117 fallen comrades, as well as recording the names of all those in the department who had served.

When the works was closed, the memorial was dismantled, with parts stored in several locations for many years (some were discovered in the undercroft at Manchester Victoria station).

In 2019, these disparate parts were reunited and restored to their former glory, with funding from multiple sources - including the Railway Heritage Trust. Following a rededication ceremony the memorial now has pride of place at Newton Heath.

The new four-road St Mary’s Shed is light-years ahead of the old depot building in terms of facilities, cleanliness and capacity - and the fleet it maintains.

On roads 1 and 2, Mechan Ltd built an engine removal table system. Pits allow trollies to be positioned under the train and used to slide power packs to an area where they can be collected by forklift truck.

A crane is installed to move heavy equipment to areas for servicing. The power packs can be stripped and rebuilt adjacent to road 1, where spares are already waiting (such as a full set of air and hydraulic hoses displayed on coloured boards such as red for ‘Hydro side’ or green, ‘Rad side’). Cabinets with all the tools required for the jobs are kept on hand.

On the 125-metre-long road 4, 16 ‘Eurogamma’ 15-tonne power jacks have been installed. These are strong enough to lift a four-carriage, 96-metre-long train, allowing all the bogies to be changed in one go.

Previously these carriages would have needed to be split to allow undercarriage components such as engines and wheel sets to be replaced. Having the ability to lift a whole train in one go speeds up renewals, allowing trains to re-enter service sooner.

Three sector plates outside the shed on roads 1, 4 and ‘195 siding’ allow whole bogies to be moved around for stripping, maintenance or removal off-site. Wheeled rafts can hold bogie frames which are placed on the east end of road 1 for component exchange or overhaul.

The shed’s two centre roads feature raised tracks to facilitate working below the solebar, while raised walkways at solebar and roof height allow for safe access to the train’s interior or roof level, where the HVAC units are fitted to Class 195s.

During my visit, several Class 195s were present, as the fleet are currently undergoing scheduled maintenance on their bogies.

These are removed when the units are lifted by the jacks on road 4. Old wheelsets are then sent away for attention and replaced by freshly overhauled ones brought in from off-site.

The past

The depot has undergone several incarnations since it was opened by the Lancashire and Yorkshire Railway in 1876.

Then, it was part of a vast railway complex that spanned both sides of the line between Manchester and Rochdale. Now, only the depot remains.

The story starts in 1839, with the formation of the Manchester and Leeds Railway. That same year it built a roundhouse, plus a locomotive and carriage works, at Miles Platting (Manchester).

In 1847, the company was absorbed into the Lancashire and Yorkshire Railway. The L&Y built more than 500 locomotives at Miles Platting, before construction ended in 1899.

The site had continued to grow in a piecemeal fashion, despite suffering a serious fire that destroyed 16 engines in April 1873. But it was clear that the railway had outgrown the site, so the L&Y directors took action.

They bought land at Horwich to build a brand new locomotive works, as well as land at Thorpes Bridge - a mile east of the existing site, between the Rochdale and Oldham lines. On the opposite side of the Rochdale line, the L&Y built a new carriage and wagon works.

The site of the original locomotive and carriage works to the west of Thorpes Bridge is now occupied by Metrolink’s Central Park tram shop and the Greater Manchester Police HQ. No trace remains of the railway works.

The same is true of the ‘new’ C&W works, which has become a housing estate. It’s hard to imagine today, but these combined sites covered over 40 acres and employed more than 2,000 people (and changed sporting history - but more of that later).

The first Newton Heath locomotive depot opened in 1876. The shed building, which covered three acres, had 24 through roads. The four on the Southern end formed a repair shop which was nicknamed ‘the Parlour’ by shed staff - a name used to this day.

The building cost £40,000 and was modelled on London and North Western Railway designs, with the roof having six hipped sections. The site was also provided with two coaling stages and two 42ft turntables.

At its peak, the depot accommodated more than 200 freight and passenger engines, providing power for a handful of express services to the Lancashire coast and to Bradford, while most engines were allocated to local services, coal trains across the Pennines, or shunting the vast network of freight sidings and yards around the L&Y network in the twin cities of Salford and Manchester.

In 1923 the L&Y was absorbed by the London, Midland and Scottish Railway.

In 1935 it modernised the shed, added a 300-ton capacity concrete coaling tower, and replaced the shed roof (except over ‘the Parlour’, which became four dead end roads).

The north end of the yard was extended across Dean Lane, having originally run beside the Railway Hotel and beneath Newton Heath station, and a new, larger 70ft turntable was added to accommodate express engines such as the ‘Patriot’ 4-6-0s.

A handful of these were allocated to Newton Heath, working services to Glasgow, before being replaced by the famous ‘Jubilee’ class.

Little changed until later BR days in the 1960s, by which time the railways were shrinking.

Steam was being replaced by diesels, and a maintenance facility for the new traction was begun in 1960. By 1961, half the shed had been rebuilt to accommodate diesel units and the ‘Parlour’ re-tracked.

This mix of traction proved damaging to the new entrants, which were often stabled next to steam, playing havoc with their electrics.

Finally, on July 1 1968, the depot closed to steam. A year later, demolition of the remaining parts of the steam depot began. The turntables were stripped out, and on July 12 the first attempt was made to demolish the coaling plant with explosives.

Apparently, it didn’t go well. It’s reported that it leaned at a crazy angle for several weeks before finally succumbing.

In 1971, the diesel shed was extended and a single-road washing facility was erected on the coal tower site, leaving the refurbished ‘Parlour’ as the only part surviving from steam days. The depot also gained a two-road fuel and inspection shed

While the depot still saw visiting locomotives for fuelling and servicing, its only allocation was a number of Class 08 shunting locomotives. The rest were first-generation diesel multiple units (DMUs) of Classes 104, ‘105’ and ‘108’. The three-car Birmingham Railway and Carriage Co Class 104s became the most famous.

Following complaints about rough riding, some received uprated suspension which was denoted by a white stripe along the bodyside.

Newton Heath carried out maintenance up to C4 level on all the fleets, and even converted some Class 127s to parcels units by fitting roller shutter doors.

In 1982 BR was spilt into three sectors, with Newton Heath falling under the patronisingly named ‘Provincial’ sector. The title was changed to the (not much better) ‘Regional Railways’ in 1989.

At that time the second-generation units were taking over. Class 142 ‘Pacers’ arrived in September 1985, followed by a small batch of Class 150/2 ‘Sprinters’ in 1987.

Under Regional Railways the depot was scheduled for closure. The remaining Class 104s and ‘108s’ were transferred to Chester in 1989, while some ‘142s’ went to Leeds Neville Hill.

The move across the Pennines wasn’t a success. The units were rapidly moved back and Newton Heath was reprieved. By 1996 its books contained 54 ‘Pacers’, 18 x ‘150/1s’, 12 x ‘150/2s’, 12 single-car ‘153s’, 18 x ‘156’ ‘Super Sprinters’ and 13 Class 158s - a total of 127 units. Not bad for a depot slated to close just seven years earlier!

Upon privatisation on April 1 1994, Newton Heath became the responsibility of Railtrack, before passing to Network Rail on the dissolution of Railtrack on October 18 2002. Railtrack did spend some money on the depot - £1.8 million was invested on roof repairs and staff facilities. But beyond that little changed.

In March 1997 the depot became the main base for the First NorthWestern franchise. This lasted until December 2004, when the first of the ‘Northern’ branded franchises took over the reins until March 1 2020, when Northern was taken back in-house by the Department for Transport.

In 2020 the last ‘Pacers’ disappeared, with the final one running into Manchester Victoria on November 27 2020. Their demise led to the biggest changes to the depot since the end of steam.

There has always been a mutual respect between the armed forces and the railways.

With the contraction of the military, many ex-service members have found new careers on the railways. Among them is Thomas Power (32), a Performance Improvement Specialist with Northern.

Tom joined the army at 16, serving in the Royal Electrical and Mechanical Engineers (REME) as a vehicle mechanic and then in production management, reaching the rank of a junior NCO.

During his time in the forces, he married and had children. His final years in the forces were spent as a STEM ambassador, working with schools and colleges to encourage recruitment into the armed services.

With a young family, he began to consider his future and life outside the forces - not an easy task in 2020 and the ‘COVID years’.

After applying for more than 300 jobs, but having secured only three interviews, Tom was looking for inspiration.

He found it one day when he was walking along his local canal with his wife. They watched a Northern train flash past and Tom thought: “Hang on, maybe the railway’s an opportunity?” He could use the skills he’d learned in the military.

Tom secured an interview for a job as a Shift Production Manager with Northern. He was unsuccessful, but he was put forward for a Supervisor role at Wigan Springs branch depot.

With just one month left of his 12-month notice period from the army, Tom then applied for a vacancy as a fitter. He was successful… but there was an unexpected ‘catch’.

“Little did I know that the fitter role was actually a dual role with a depot driver role,” he recalls.

This meant he suddenly found himself undergoing medical and psychometric testing, to be passed to undertake driver training. Tom describes this unexpected turn

For me, inspiring young people is the most priceless thing that you can do.

Roof repairs and enhancements have led to two of the four through roads in the legacy shed being blocked while the work is carried out by GallifordTry.

CASE STUDY: Thomas Power

The saga of ‘Pacer’ train replacement is worthy of its own article, but here’s a brief rundown.

By the mid-2010s ‘Pacers’ had become increasingly unpopular with passengers, the media and some politicians. Seen as the antithesis of the then-government’s slogan of ‘levelling up’, they became something of a political football.

The new Northern franchise winner (Arriva) wanted new trains. So did passenger groups and the Transport Select Committee. The DfT didn’t, as they weren’t ‘value for money’.

It took a Ministerial Directive from Transport Secretary Patrick McLoughlin to get them ordered. Spanish company CAF won the tender for 58 trains, comprising 25 two-car and 33 three-car DMUs, all of which would be allocated to Newton Heath.

There was only one problem. Originally, the new trains were expected to be maintained in the old shed, alongside the BR-built ‘legacy’ fleets - which is a bit like trying to maintain a modern racing car in a workshop built for a model T Ford. Plus, the old shed needed some serious work doing to its roof.

In the end, it was decided to build an entirely new £20m shed at the eastern end of the depot, on the former turntable site alongside St Mary’s Road.

In 2018, Arriva awarded a design and build principal contract to Stobart Rail & Civils for a steel portal-framed building, 135 metres by 24 metres, that includes four 125-metre-long maintenance roads alongside a 113-metre-long and six-metre-wide side annexe to house stores, offices, toilets and kitchen facilities for the depot team.

To build the shed, 50,000 tonnes of soil were removed from the site to improve ground conditions and levels, before 521 steel piles were sunk to support the structure.

The new shed was completed in June 2020. At the same time, Stobart Rail & Civils built the new wheel lathe facility.

The future

While the legacy BR-built fleets have several years’ life left in them, Northern has begun the process of replacing them, asking for expressions of interest in building new bi-mode and tri-mode trains.

If and when an order is placed, there’s little doubt that Newton Heath will continue to be a centre for servicing and maintaining them - although what changes will be needed to the depot’s buildings and track layout is anyone’s guess at this stage.

Whatever is decided, Newton Heath should still be around to celebrate its 200th year of railway operations in 2076. Not bad for a depot once slated for closure!

Case Study: Thomas Power

There has always been a mutual respect between the armed forces and the railways.

With the contraction of the military, many ex-service members have found new careers on the railways. Among them is Thomas Power (32), a Performance Improvement Specialist with Northern.

Tom joined the army at 16, serving in the Royal Electrical and Mechanical Engineers (REME) as a vehicle mechanic and then in production management, reaching the rank of a junior NCO.

During his time in the forces, he married and had children. His final years in the forces were spent as a STEM ambassador, working with schools and colleges to encourage recruitment into the armed services.

With a young family, he began to consider his future and life outside the forces - not an easy task in 2020 and the ‘COVID years’.

After applying for more than 300 jobs, but having secured only three interviews, Tom was looking for inspiration.

He found it one day when he was walking along his local canal with his wife. They watched a Northern train flash past and Tom thought: “Hang on, maybe the railway’s an opportunity?” He could use the skills he’d learned in the military.

Tom secured an interview for a job as a Shift Production Manager with Northern. He was unsuccessful, but he was put forward for a Supervisor role at Wigan Springs branch depot.

With just one month left of his 12-month notice period from the army, Tom then applied for a vacancy as a fitter. He was successful… but there was an unexpected ‘catch’.

“Little did I know that the fitter role was actually a dual role with a depot driver role,” he recalls.

This meant he suddenly found himself undergoing medical and psychometric testing, to be passed to undertake driver training. Tom describes this unexpected turn of events as “a big learning curve”, but he passed and qualified.

I ask Tom what were the challenges in making the transition to civilian life?

“A job outside the military was hard enough to adjust to. I’d always had this status of being in the military, but how do I operate in a civilian company that’s a profitable business?”

What it was like not being told what to do as much?

“To have free rein to have my hands in my pockets and walk across grass was luxury! I’m definitely more relaxed now.”

After bedding into civilian life, learning the railway ropes at Springs Branch, and moving up from fitter to Supervisor, Tom applied for a couple of roles at Newton Heath.

He was successful in attaining his current position as Performance Improvement Specialist, taking up the role in December 2023. How does he find working to encourage young people into the industry?

“For me, inspiring young people is the most priceless thing that you can do,” he replies enthusiastically.

I quiz Tom on what he thinks attracts people from the services to the railways.

“What I’ve experienced is a similar level of camaraderie, and that sort of family feeling that you get anywhere you work. You’ll always get the social side of it, but I feel that in the railway it’s a much closer-knit group.”

The old adage about the ‘railway family’ is borne out in Tom’s words. He also reflects on the rapport between the two - illustrated by memorials across the network to rail workers killed on active service during wartime, such as the one in the ‘Parlour’ at Newton Heath.

“There’s quite a link between world war time and people who were railway workers, and that’s continued.

“That’s not the real reason people move from the military to the railway, but there’s a natural link. There’s a lot of rapport for people who work in the railway for the military, and the other way round. There are similar environments in terms of history. People in the military have status, and I think people in the railway do too.”

Moving on, I ask Tom what he thinks the biggest difference is between the two.

After a moment’s thought, he replies: “A big learning curve I had to get my head around was unions. Anyone who’s come from the military - that’s never even in their mind. I didn’t even know what a union was!”

And now?

“After a few months in the job, I realised that this is quite important to people who work in the railway.”

Tom says he was apologetic to colleagues whom he felt he had dismissed when they first talked to him about joining a union.

“I soon realised the union was there to protect workers, protect terms and conditions, and job security - and I needed to gain that.”

Tom’s story offers a personal insight into the relationship between the armed forces and the railways, something not everyone is familiar with. Hopefully, this has helped bridge the gap.

For a full version of this article with more images, Subscribe today and never miss an issue of RAIL. With a Print + Digital subscription, you’ll get each issue delivered to your door for FREE (UK only). Plus, enjoy an exclusive monthly e-newsletter from the Editor, rewards, discounts and prizes, AND full access to the latest and previous issues via the app.

Login to continue reading

Or register with RAIL to keep up-to-date with the latest news, insight and opinion.

Login to comment

Comments

No comments have been made yet.