Walk around Glasgow’s famous George Square, and you could be forgiven for not even noticing that there’s a railway station there… let alone the third busiest in Scotland.

Glasgow Queen Street, located to the northwest of George Square, is not only the gateway to the Highlands, it is also the terminus for trains to Edinburgh Waverley.

It’s a vital link for the prosperity of Scotland, with a shuttle service linking the two major financial powerhouses in Scotland. A 15-minute frequency means four trains per hour run between Edinburgh and Glasgow on the busiest and most important of four routes between the two cities.

It is often described as the ‘flagship’ route north of the Border, and from this December electric trains will be running along the route. Initially Class 380s cascaded from routes in Ayrshire will be used, but next year brand new Class 385s will be introduced.

To accommodate these new trains, changes are needed to the infrastructure at Queen Street, with longer platforms needed and the erection of overhead wires. Network Rail has combined that with the need to introduce a better quality station - one that, when it is finished, people in George Square will not be able to overlook.

Glasgow Queen Street’s current predicament is similar to that of London King’s Cross before the latter’s transformation. Impressive architecture has been buried beneath a 1970s-designed building that hid the station’s ‘good looks’. But this building will be swept away this summer, and eventually a glass-fronted building will be constructed, allowing more natural light into the station concourse. Platforms will also be extended and a remodelled concourse will be laid out for passengers.

But that’s in the future. From March 20 the station will be closed until August 8. The 20-week closure is necessary to enable other work to take place that complements the £742 million Edinburgh-Glasgow Improvement Programme (EGIP).

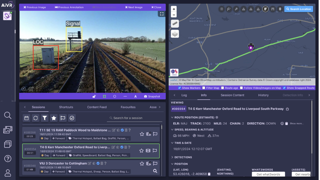

There is plenty of infrastructure work about to start. At Cowlairs, five point ends at the South and West Junctions will be renewed and four point ends at the West Junction will be refurbished. Additionally, around three kilometres (1.8 miles) of plain line track will be renewed.

In Queen Street Tunnel, Network Rail will remove 10,000 tonnes of existing concrete slab, and install new twin-track OBB Porr Slab track through the tunnel (918 metres), as well as four new sets of switches and crossings, new drainage, 4,000m of new rail, and a conductor bar that will be used for electrification.

The first three weeks of the blockade focuses on the work at Cowlairs. “We said right, OK, we don’t want to have this massive 17-week blockade and then upset people on a subsequent number of weekends,” Network Rail’s EGIP Programme Manager Paul Reilly tells RAIL, explaining that the work at Cowlairs would otherwise have involved a series of weekend closures.

This is the first time that work has been carried out in the tunnel in around 40 years. The infrastructure is life-expired. And there are other factors to consider, according to Reilly. Those renewals in the 1970s were carried out at weekends, meaning that the teams were ‘always chasing the clock’.

The tunnel was being dug out and concrete poured in, but the water wasn’t managed properly, he suggests. And with natural springs in the ground surrounding the tunnel, that factor is important.

“There are canals and streams and all sorts running over the top of it. So quite a lot of water finds its way into the tunnel.”

Reilly says the tunnel is in good condition and fairly secure, but nevertheless the slab track needs securing. NR must dig down at least 1.5 metres, depending on the rock type, to secure the track.

“There’s a hydrostatic pressure which could break it,” he explains. “So we’re putting some dowels down to hold the slab track onto the bedrock. And we’re putting in a deep six foot drain to remove all the water from there.”

Furthermore, the tunnel is on a 1-in-40 incline, which will affect what plant can and cannot be used. Runaways also need consideration.

The site will be split into platforms, the throat and the tunnels. Up to 100 people could be working per shift, and three shifts will work around the clock.

The conductor bar for electric trains will be installed along the length of the tunnel and will be directly fastened into the tunnel lining. There will be seven metre centres, so there’s no catenary system - the bar just spans between the supports. This was the system installed in Winchburgh Tunnel and also tunnels at Princess Gardens in Edinburgh.

Access must be tricky for the teams, however. Reilly explains: “We’ve got access from the north through to the tunnel. There are also two tunnel airshafts we’re going to use to supply concrete into the tunnel. We’ll set pumps on top of them to pump concrete into the tunnel. It’s not an easy job… it’s not a great location, but we can’t move it. One of the key interfaces is managing the site compound along with ScotRail passengers.”

He adds that when NR builds the station frontage area, that will be done while the facilities will remain in use: “The station will be used as it is today. We’ll knock the building down and build a new one.”

The Queen Street project has been ongoing (Reilly says he has been working on it for two years), with preparatory work for the slab-tracking carried out at Christmas.

Reilly explains: “The slab-track system is a three-part system. There’s a base slab we’re going to install. It’ll knock the slabs out and at these points we’ll put in a spigot or spindles - that makes the lines level of the slab track. When we’ve sufficiently put these in we’ll put a length of rail in for 100 metres or so. Then we’ll fine-tune the position of the slab track of the rails so the geometry is perfect. There’s a self-compacting concrete, which we pour into these gaps. We just pour the concrete in, which fills the sides in.”

Once the concrete ‘cures’ the system is ready to go: “Essentially it’s all ours, we can run a whole rail track over it. In three days you can run trains over it. Once you’ve got the old base slab out and the new base slab in, the job becomes fairly straightforward.”

A production line will then work its way through the tunnel. Reilly explains: “We start around the Up line, which is the Edinburgh line - the Glasgow end of it - and we break the existing slab out and head towards Edinburgh. Basically remove the slab and then once you’re so far ahead you start installing the new base slab. Once that’s up ahead you start putting in the slab track.”

Attention then turns to the Down Line, going in the same direction.

“It’s easier. If you try to pour the concrete on the top end it just runs down. So you need to start at the bottom end and work your way up. You clean the site behind you, so what you’re cleaning you can work on, as long as you have trains in that are bringing sufficient supply of the panels - and we’re going to have a stack of these in the station.

“Something’s going to have to stop work to allow a train coming past us. But the beauty of doing one line at a time is you’ve always got a working line. You’ve got a way in and out.

“Queen Street is pretty straightforward because it’s all a pretty consistent gradient. Winchburgh had a bit of a dip in it, so mining out water was more problematic.

“Going to our methodologies, we’re going to install a drain as we go. Then there’s always an outlet for water, which will go all the way along that base slab, so we’re never going to be swimming - we’ll have our outfall.”

Reilly is not expecting any surprises. “We are going to encounter spring water at certain times, but we’ve got a plan. One of our designs is we can capture that and channel out water. We manage that water at a one-off level, so it doesn’t impact into the build.

“We won’t flood Queen Street - there’s a lot of drainage alterations in the station. The system’s been bastardised over the years, adding bits in here and there to try and solve it - sticking plaster. But we have a once-in-a-lifetime opportunity to rip out what’s there and put in a robust system.”

If that’s not enough, platforms will be extended at Glasgow Queen Street station throat, all seven switches & crossings units will be renewed, new drainage will be installed, and signalling will be renewed.

During the entire process the Low Level station will remain open, as will the High Level concourse, although that will be heavily managed.

The slab tracking work is not part of EGIP, but the Queen Street redevelopment is. However, Reilly explains that you cannot do one without the other.

“The slab tracking is being done by EGIP, but only because it’s a life-expired asset. The track route asset manager said we can’t embark on EGIP and start running longer, faster electric trains on top of slab track which is opening up in front of us.”

The work about to take place at Queen Street was originally planned as a 17-week blockade, but has been extended to 20 weeks. Initially, Platforms 3, 4 and 7 will be extended to accommodate eight-car trains, although until 2019 only seven-car trains will run. Each platform will also be electrified. Trains using Platforms 3 and 4 will be able to go straight into the tunnel from the station, and be dedicated Edinburgh-Glasgow platforms. Trains using these platforms will not need to use crossovers in the tunnel.

So how will the extension be done?

Reilly explains: “Basically, on an existing concourse, we take out the platform wells on Platforms 2, 3, 4 and 5 and extend right into the existing concourse.

“If you order a shorter one in there that’ll go with the short width. And at some point later on this year we’ll start knocking down Consort House, the office block and the hotel extension. They’re being compulsorily purchased under a tourist scheme.”

While all this work is taking place, the station will remain operational. Unlike at King’s Cross, where two platforms were removed from service at various times to enable work to be completed, Reilly’s team will keep Queen Street station running.

“We’re going to do the platform wells, extend the platforms during the blockade, and cover them over. We can do about 75% of the platform well extensions during the blockade in the summer. Then when we come to knocking the buildings down, we can finish the platform wells. We’ll have to start thinking about concourse space to do the final extension to the concourse and the platform wells.”

But surely it would be easier to do it in one go, and get the station ready for eight-car trains now? After all, the ‘385s’ initially being delivered will be four-car trains, so they could operate as eight-car formations.

Reilly responds that the trains cannot be extended until the new concourse is created.

In terms of what NR is planning on the concourse itself, passengers walk onto it now and encounter a concourse that is quite small for a station of that magnitude. It’s also quite cluttered. If the platforms are extending right to the end of the new concourse, how will NR look to transform that?

Reilly explains: “It comes from a big glass box. It becomes a bigger area. The existing train shed is quite a nice feature of Queen Street, but you can only see it from the north side. The new building does allow you to see it from George Square, and it becomes a feature in its own right from George Square.”

Access will also be improved. “Any entrances or exits you have to use, you go through a narrow grubby stairway. It’s just not a nice way in and out of Queen Street. That will all change with the new building.”

In the early 1990s the Buchanan Galleries shopping centre was built, turning the station into a more confined space than it had been previously. There were plans to extend the centre again, which would have made the station subterranean (it would have extended out across the open space at the northern end of the station). That plan is now on hold, but still created issues, as Reilly explains.

“We couldn’t start now until they’re finished at the end of August. Initially we were all getting part of the car park, under 800sq metres compound in the car park, which was going to constrain how the different bodies were hemmed in. They were going to be building a multi-storey above us, but now we have a free reign of the car park to have our site facilities - to have a main site compound.”

The close proximity of Buchanan Galleries also means that NR has no plans to make Queen Street a ‘destination station’, similar to St Pancras or Birmingham New Street.

NR spokesman Nick King tells RAIL: “The problem is with Glasgow it’s already a destination - it’s hard to make it any more attractive. To a certain extent, the retail element in the Buchanan Galleries would be a plan.”

During the blockade, Network Rail and ScotRail will erect a big marquee and there will be a queuing system in place - passengers for Edinburgh stand in one queue, passengers for Helensburgh in another queue. That will be located in the spot currently used by the taxis. By the time this issue of RAIL goes to press, the taxis will have moved to the front of the station.

When the station re-opens on August 8, it won’t resemble a building site, but passengers will be able to notice a few differences. Overhead line equipment will be up, for a start.

Reilly elaborates: “The front end will look like it does today. So passengers will come in and say: ‘what’s changed?’ It won’t be until they walk down to the platforms, when they get to the end of the platforms and realise these are longer. There’s not going to be a real change for the passengers… not yet. So I think we need to stress this is part of our Phase 1.”

Phase 2 is when they get the actual new station. Reilly explains: “The station has to be finished by 2019. And that’s the date we’ll open the new station box. But the railway works need to get done a lot earlier than that. The 2016 target is for electrification!”

It must also help having a Network Rail/ScotRail Alliance north of the border (Phil Verster is Alliance Managing Director).

Says Reilly: “As an operator it makes him more amenable to help us. So getting possessions and changing times of possessions is a lot easier.”

He says of alliancing: “It’s not really affected me. The alliance was in place last year when we did Winchburgh. It was cohesive. We were involved with ScotRail more than we had been previously.”

Glasgow Queen Street will change. Reilly is confident of this, and confident that the changes will work. By 2019, despite NR’s protests, it seems Queen Street will indeed be a ‘destination station’.

- This feature was published in RAIL 795 on March 2 2016

Login to comment

Comments

No comments have been made yet.